Product

Tìm kiếm sản phẩm

Outstanding product

HOT News

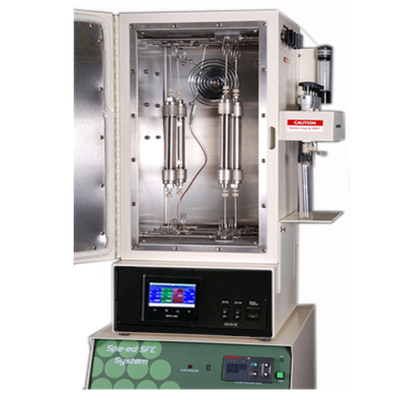

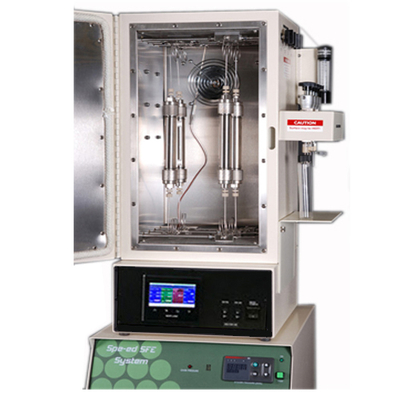

Applied Separations

Online support

Tel: 0908866933 - secovina@vnn.vn

Thống kê truy cập

- Đang online 0

- Hôm nay 0

- Hôm qua 0

- Trong tuần 0

- Trong tháng 0

- Tổng cộng 0

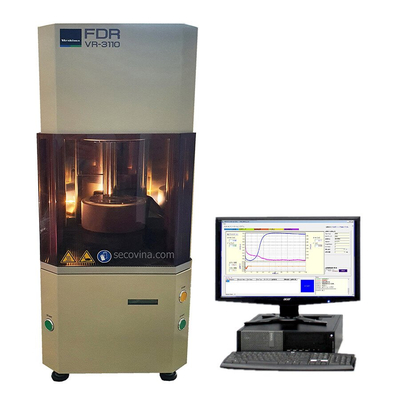

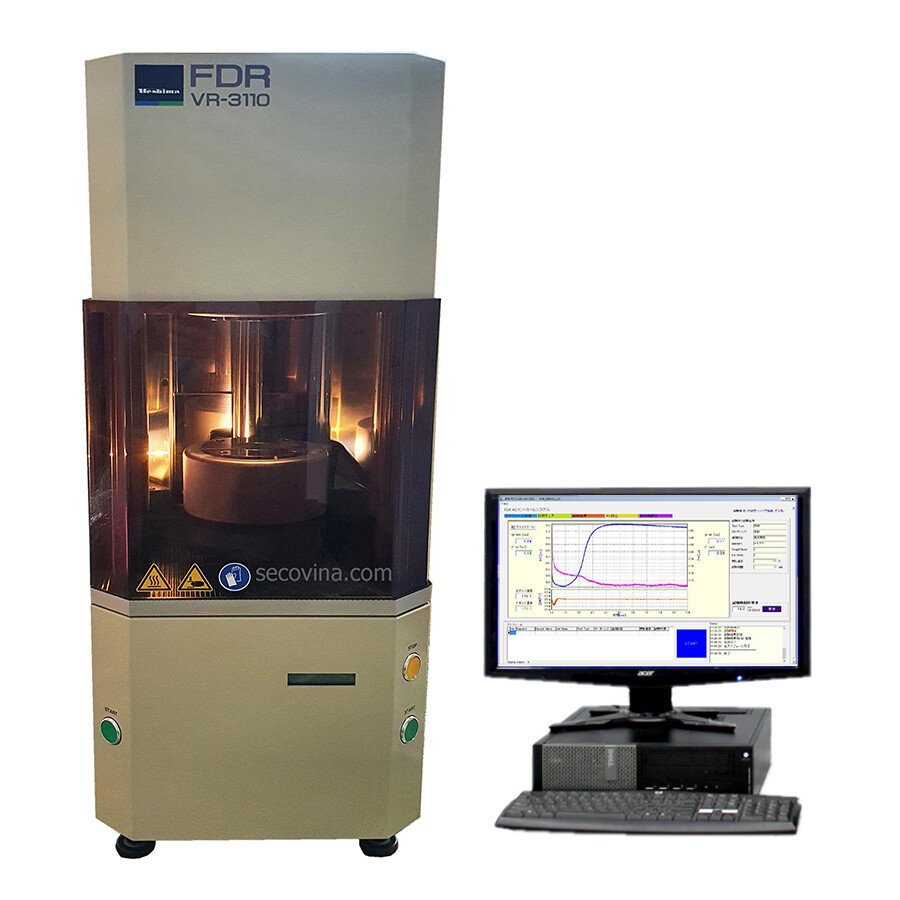

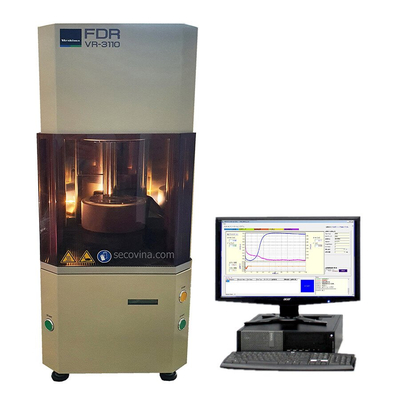

Flat Die Rheometer (FDR)

VR-3110

Ueshima

12 months

|

Name |

FDR(Flat Die Rheometer) |

|

Model |

VR-3110 |

|

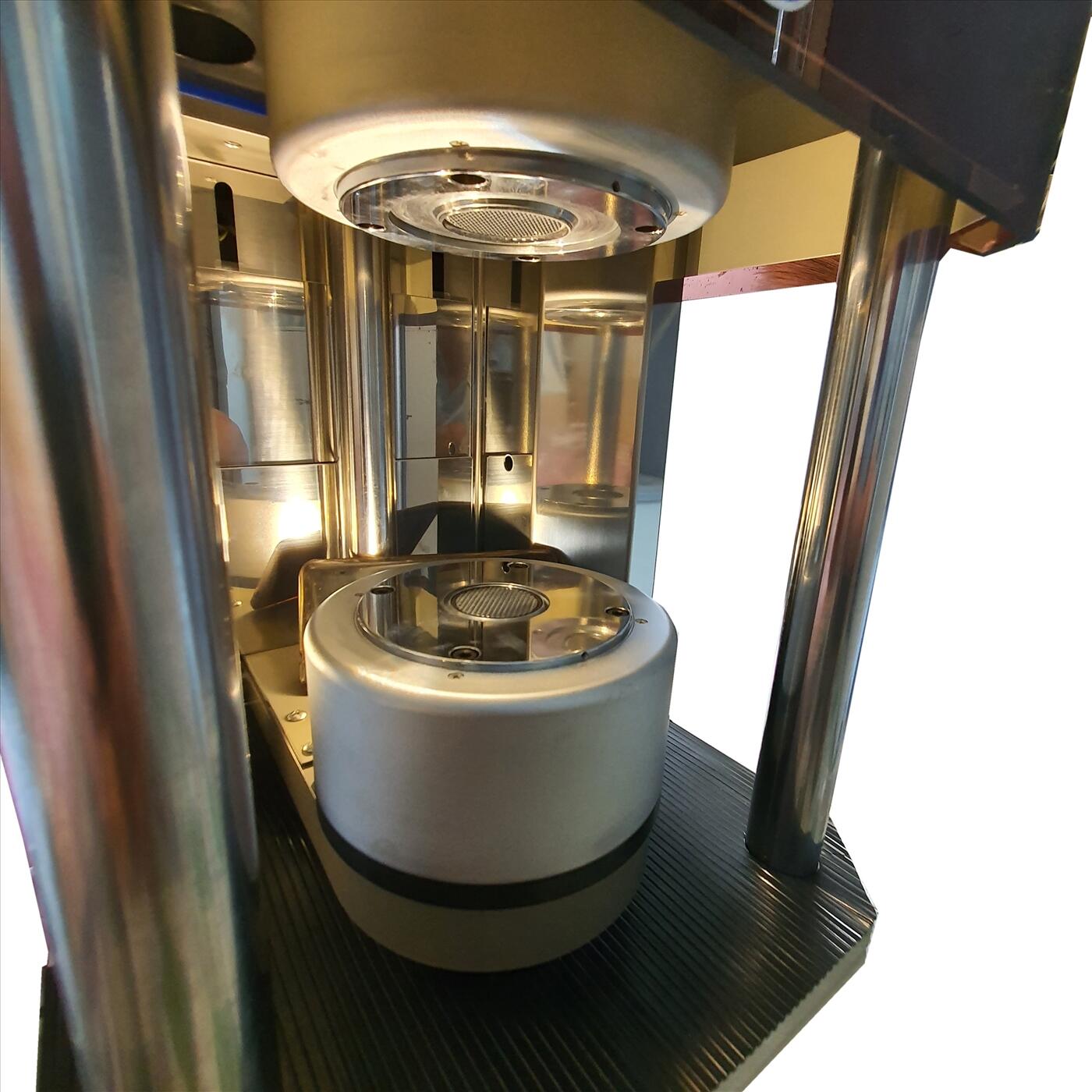

Shape of Die |

No friction flat sealed cavity(JIS K 6300-2, ISO 6502, ASTM D 5289 compliant) |

|

Pressurizing Method |

Pneumatic Cylinder (Oil-less type) Cylinder Inner Diameter: 160mm |

|

Oscillation Drive Method |

Sinusoidal Vibration Mechanism by Conical Rotational Motion “Cone Drive” |

|

Oscillation Drive Motor |

Synchronous Motor 25W AC |

|

Oscillation Transmitting Method |

Elastic Connection by Leaf Spring |

|

Frequency |

1.67Hz (100cpm) |

|

Oscillation Angle |

±1° |

|

Oscillation Angle Accuracy |

2±0.03°(Without Load) |

|

Torque Detecting Method |

Strain Gauge Type Load Cell |

|

Torque Transmission Method |

Elastic Connection by Leaf Spring |

|

Testing Temperature Range |

50 to 230° C |

|

Temperature Control Accuracy |

Die Temperature: ±0.3° C at 190° C Internal and External Die Temperature Difference: ±1.0° C at 190° C |

|

Heat Control Method |

Independent PID Control on four pieces of Film Heaters (Upper / Lower Die, Upper Outer / Lower Outer Die) |

|

Temperature Sensor |

Platinum Resistance Sensor (Pt100) 4pcs |

|

Maximum Testing Time |

9999minutes |

|

Shield Cover |

Colored Acrylic on Front and Sides (Preventing external air and for Safety) |

|

Safety Equipment |

(1) Two-hand Press Start Switch (Cylinder lifts only when both buttons are pressed simultaneously.) (2) Overload Protection (more than 22N・m) (3) Overheat Protection (Heater will be turned off at 240° C or higher.) |

|

Communications |

RS232C |

|

Utilities |

(1) Power Source AC100V/220V, Single Phase, Power Consumption less than 700VA (2) Dry Air 0.343 to 0.686MPa |

|

Environmental Conditions |

(1) Temperature 5 to 40° C (2) Humidity 35 to 80%RH (No Dew Condensation) |

|

Dimensions and Weight |

Approx.333(W)×520(D)×780(H)mm, Approx.110kg |

|

Standard Items |

(1) Equipment main unit: 1 set (2) Accessories 1set (Software, Special Tool, Minimum Consumable Parts etc.) |

Option:

●Sponging Pressure Measurement

[Application] It is useful for research/development and production line control on sponge rubber to examine

sponging pressure and relationship between blowing agent reaction and vulcanization of sponge rubber.

●Programmable Temperature Control

[Application] It simulates vulcanization of large sized rubber products, continuous vulcanization, mold vulcanization, etc. to examine vulcanization characteristics with rising temperature at a preset temperature rise.

Bình luận

Sản phẩm cùng loại