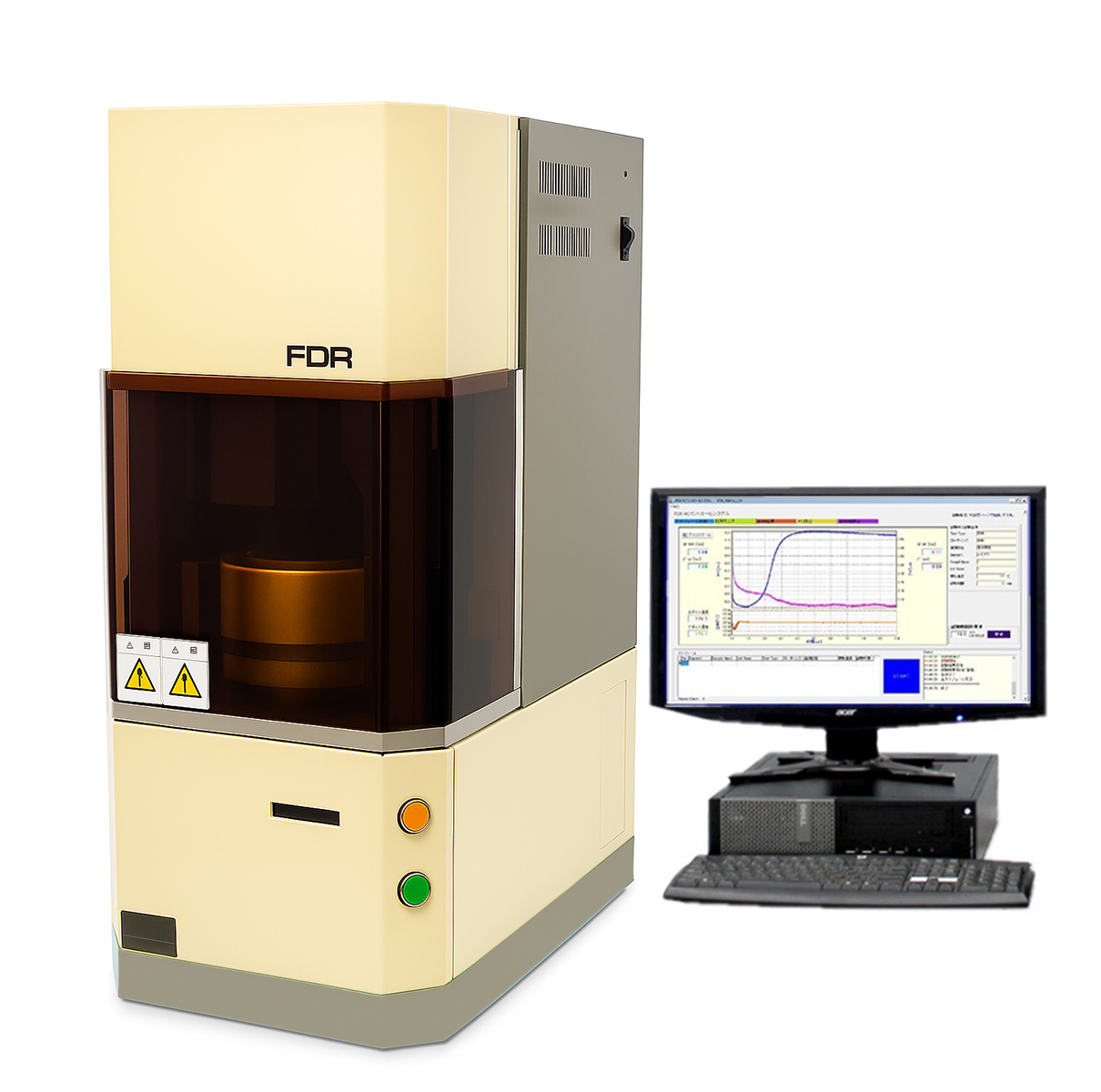

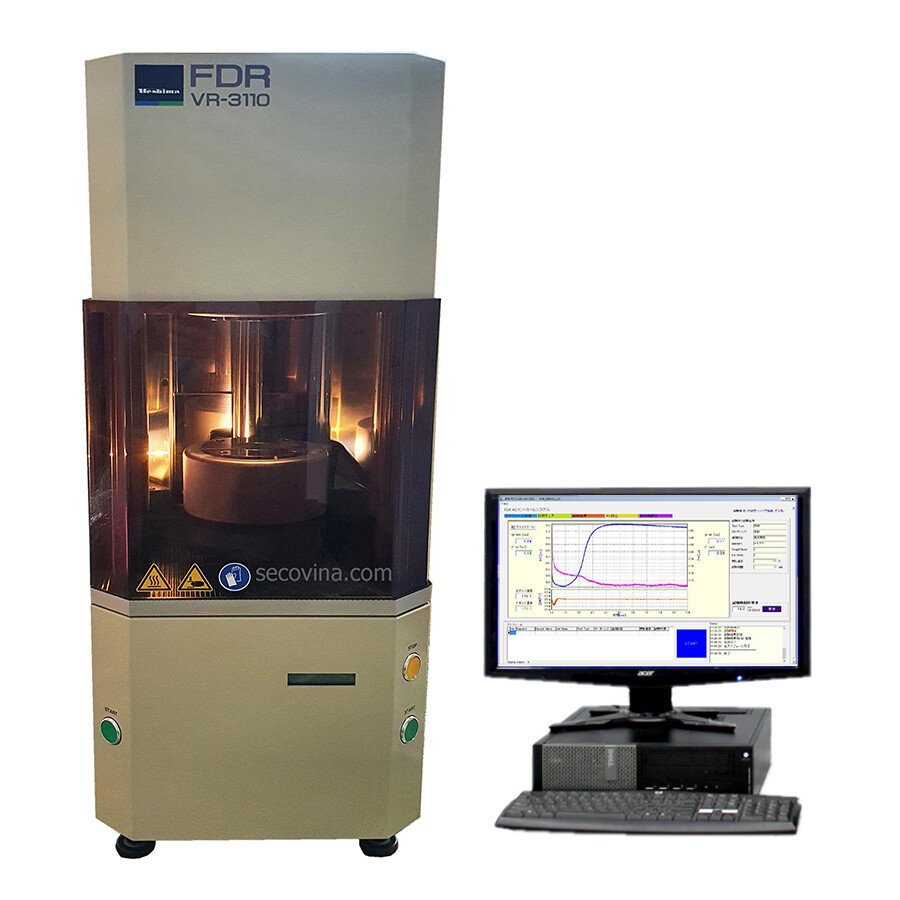

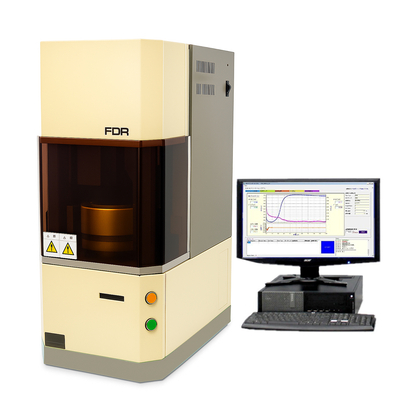

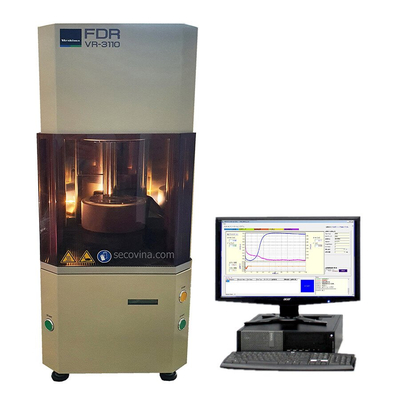

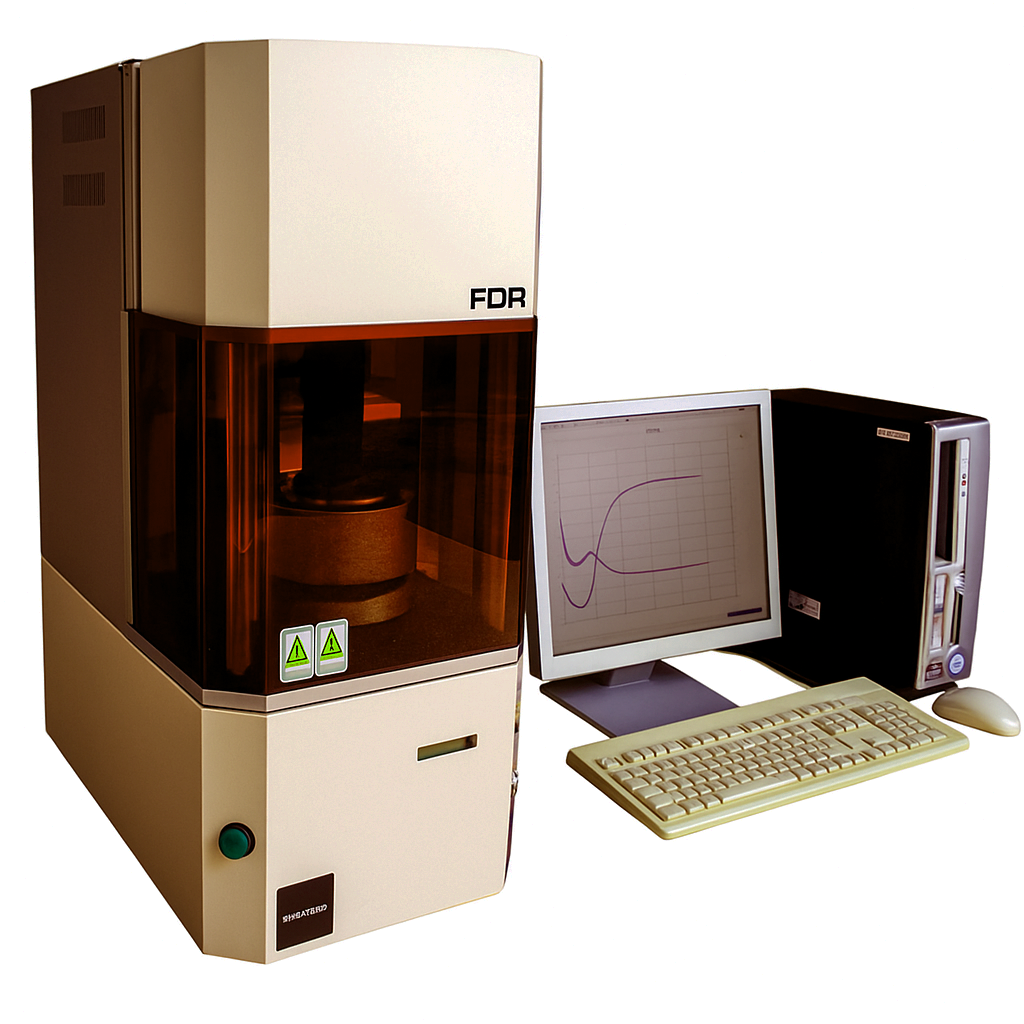

Flat Die Rheometer (FDR)

VR-3110

Ueshima

12 months

Flat Die Rheometer (FDR) VR 3110 JIS K6300-2, ISO 6502, ASTM D 5289 (Oscillating Sealed Flat Die Cavity Rotorless Curemeter) FDR (Flat Die Rheometer), manufactured by Ueshima Seisakusho Co., Ltd., 加硫試験機

secovina@vnn.vn

HOTLINE TƯ VẤN : 0908866933

Flat Die Rheometer

Model: VR-3110

Manufacturer: Ueshima - Japan

Applicable Standard : JIS K6300-2, ISO 6502

(Oscillating Sealed Flat Die Cavity Rotorless Curemeter)FDR (Flat Die Rheometer), manufactured by Ueshima Seisakusho Co., Ltd., is a high precision rubber vulcanization tester in conformity to Japanese Industrial Standard (JIS) and International Organization for Standardization (ISO). It gives small sinusoidal vibration that does not destroy the compounded rubber and expresses the torque that changes with the progress of vulcanization as a function of time (vulcanization curve), and shows the physical properties like minimum torque, the maximum torque, the scorch time, the vulcanization time and viscoelastic properties.

Application

●Measurement of vulcanization characteristics of compounded rubber along with the vulcanization process.

●Measurement of viscosity of raw and compounded rubber

Outstanding Features

●Excellent Temperature Control by 4HD (4 Heater Drive)

(Film Heaters are adopted and each of them is controlled by PID.)

・Shortened warm-up time.

・Shortened temperature recovery time after placing a sample.

・Excellent repeatability of test results.

●Compact and Lightweight (Minimized installation space)

●Conical drive, which adopts conical rotary movement, realizes an accurate sinusoidal oscillation.

●Simple Calibration System

・ Automatic Calibration of Load Cell by Electric Calibration System

・ Automatic Calibration of Phase and Torque by a Dynamic Calibrator

●Easy Operation and Data Management by PC

・ The measurement results can be easily exported to spreadsheet software like EXCEL, enabling easy preparation of reports, histograms and control charts.

●Unitization of Each Unit for Easy Maintenance

・ Heater, load cell and other input / output related amplifiers are unitized into a PCB in the machine.

・ Supply of units such as heater and temperature sensor

Measurement Principle

By placing compounded rubber between the upper and lower dies at a specified temperature, it measures torque which varies with rubber vulcanization while being subjected to sinusoidal torsional vibration. The vulcanization characteristics can be obtained while tracing changes in viscoelasticity during vulcanization process.

Applicable Standard: JIS K 6300-2, ISO 6502

Shape of Die: No friction flat sealed cavity(JIS & ISO compliant)

Pressurizing Method: Pneumatic Cylinder (Oil-less type) Cylinder Inner Diameter: 160mm

Oscillation Drive Method: Sinusoidal Vibration Mechanism by Conical Rotational Motion “Cone Drive”

Oscillation Drive Motor: Synchronous Motor 25W AC100V

Oscillation Transmitting Method: Elastic Connection by Leaf Spring

Frequency: 1.67Hz (100cpm)

Oscillation: Angle ±1°

Oscillation Angle Accuracy: 2±0.03°(Without Load)

Torque Detecting Method: Strain Gauge Type Load Cell

Torque Transmission Method: Elastic Connection by Leaf Spring

Testing Temperature Range: 50 to 230°C

Temperature Control Accuracy: Die Temperature: ±0.3°C at 190°C

(Internal and External Die Temperature Difference: ±1.0°C at 190°C)

Heat Control Method: Independent PID Control on four pieces of Film Heaters (Upper / Lower Die, Upper Outer / Lower Outer Die)

Temperature Sensor: Pt100 4pcs

Maximum Testing Time: 9999minutes

Shield Cover: Colored Acrylic on Front and Sides (Preventing external air and for Safety)

Safety Equipment:

(1) Two-hand Press Start Switch (Cylinder lifts only when both buttons are pressed simultaneously.)

(2) Overload Protection (more than 22N・m)

(3) Overheat Protection (Heater will be turned off at 240°C or higher.)

Communications RS232C

Utilities:

(1) Power Source: AC100V, Single Phase, Power Consumption less than 700VA

(2) Air Source: Dry Air 0.343 to 0.7MPa

Dimensions and Weight: Approx.333(W)×520(D)×780(H)mm, Approx.110kg

Standard Items

(1) Equipment main unit: 1 set

(2) Accessories 1set (Software, Calibration Kit, Special Tool,)

Bình luận

Sản phẩm cùng loại

Constant-stress/strain flexometer

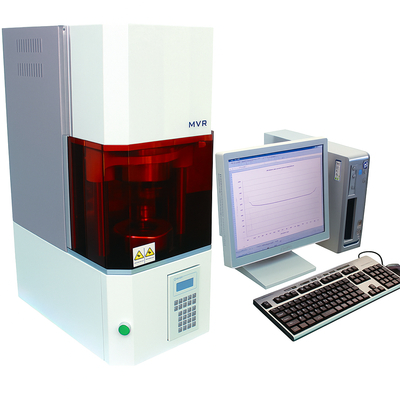

Mooney Viscometer

Dynamic Mechanical Analyzer (DMA)

Maron Type Mechanical Stability Tester

VR-6155

AB-1150 LAMBOURN ABRASION TESTER

FPS WEAR TESTING SYSTEM

TR Tester

Akron Abrasion Tester

Dupont Impact Tester

GEHMAN’S TORSION TESTER

Cable Abrasion Tester

Durometer Shore A - Shore D

Low Temperature Brittleness Tester

RTM Friction Tester (Tire)

latex mechanical stability tester

GEER’S AGING OVEN

Tensile testing machine

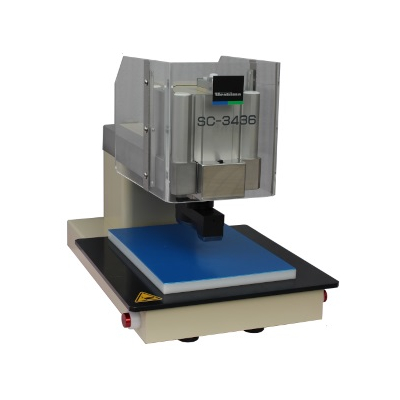

Pneumatic Drive Press Cutting Machine

Akron Abrasion Tester

DIN Abrasion Tester

DEMATTIA FLEX CRACKING TESTER

Fanpage