Laboratory Scale Supercritical Systems

OV-SCF-10000C

Applied Separations

12 months

The OV-SCF-10000C are the original SFEs in our series of instruments for supercritical fluid extraction. These systems were designed to meet the rigorous needs of day-to-day use in the research lab. They are simple to operate, fast and affordable, with unique features not found in other SCF systems.

secovina@vnn.vn

HOTLINE TƯ VẤN : 0908866933

OV-SCF-10000C Oven Extraction Equipment

A. System Requirement

1. Power supply: 220V, 10A

(Include B-1. OV-SCF: Extraction Oven & B-2. PM-10000C: Digital Pressure Control Module)

2. Driven air: compressed dry air or general air (6~8 kg/cm²)

3. Cooling water: ≤5°C

4. LCO₂ supply

B. Detail Specifications

B-1. OV-SCF: Oven Extraction Furnace

1. Operation temperature: room temperature ~220°C (max).

2. Temperature control: heating rate ≥10°C

3. Output pressure: 1500 ~ 7250 psi

4. Operation capacity:

o High-pressure extraction vessels with size ranging of 60ml, 250ml, and 1.0L can be installed in OV-SCF and exchanged as needed.

5. High Pressure Extraction Vessel: 1 Liter

6. Double extraction loop: capable of 2 extraction set.

7. Extraction mode: continuous or batch extraction.

8. Cleaning method: capable of solvent injection device.

9. Flow control: tunable control with display of gaseous CO₂ flow rate.

10. Certification: IEC61010-2-010 (2nd Ed) for use with IEC61010-1:2001, certificate number: 97-0768.

11. Power supply: 220V, 10A

B-2. PM-10000C: Digital Pressure Control Module

1. Output pressure of system: 1500~7250 psi (depends on pressure of gas source).

2. Pneumatic pump

a. Output pressure: MAX 7250 psi.

b. Flow rate: 200 ml/min (under 4350 psi).

3. Heat exchanger inside (not include water chiller).

4. Safety protection system

a. Alarm of over-pressurization.

b. Alarm of operating timer.

c. Emergency stop and automatic gas-cut device for over-pressurization.

d. Pressure relief valve (full port type).

5. Touch panel control system.

6. Certification: IEC61010-2-010 (2nd Ed) for use with IEC61010-1:2001, certificate number: 98-0192.

7. Embedded communication Prot (USB/RS232) to support output device (printer).

8. Power supply: 220V, 1A

C. Water Chiller

1. Power supply: 220V, 7A

2. Operation temperature: -20°C ~40°C (max).

3. Temperature control: PID Automatic Algorithm.

4. Recycle Pump: SUS recycle pump.

5. Pump flow rate: 8L/min, 0.2kg/cm²

6. Compressor: 1/3Hp, 750Kcal/hr

7. Capacity: 10L

ESP-010B: Co-solvent pump

1. Flow rate: 0.01 ~ 9.99 ml/min

2. Display: LED digital display

3. Pressure: Max 5500 psi

4. Pump: SUS316

5. Accuracy: ±2%

6. Precision: ±0.2%RSD

7. Digital flow rate setting

8. Configure check valve

9. Dimension: 415 x 297 x 330 mm

10. Power supply: 220V / 1A

11. Pipeline: 1/8” seamless stainless steel pipe

12. Safety device: safety valve (Setting pressure: 5500 psi)

13. High pressure needle valve

14. Analogical pressure gauge

Vessels:

1. Volume: 60 ml

2. Operation Pressure: 500 Bar (max)

3. Operation Temperature: 200°C (max)

4. Upper and lower cover design of the vessel

1. Volume: 250 ml

2. Operation Pressure: 500 Bar (max)

3. Operation Temperature: 200°C (max)

4. Upper and lower cover design of the vessel

1. Volume: 1000 ml

2. Operation Pressure: 500 Bar (max)

3. Operation Temperature: 200°C (max)

4. Upper and lower cover design of the vessel

Power System

1. Power: 4.5 HP

2. Working Pressure: 0 ~ 8 Kg

3. Tank Volume: 60 L

4. Voltage: 220V / 50Hz / 13A

5. RPM: 1720

6. Displacement: 360 L/Min

7. Weight: 38 Kg

8. Dimension: 67 x 33 x 75 cm

Bình luận

Sản phẩm cùng loại

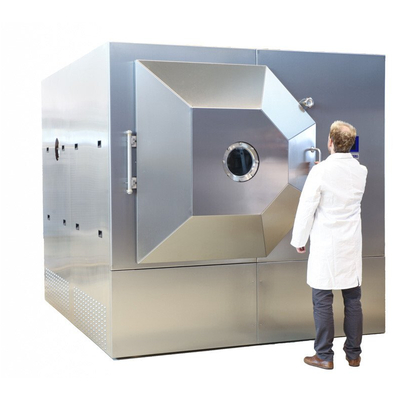

Pharma laboratory Freeze dryer

Lab Freeze Dryer

Vaccine Freeze dryer Sublimator 80-3

Pilot/Laboratory Freeze Dryer

Vaccine Freeze Dryer

BII-S151 Laboratory Spray Dryer

Fanpage