ISO 6502

Summary of ISO 6502 – Rubber — Guide to the use of curemeters:

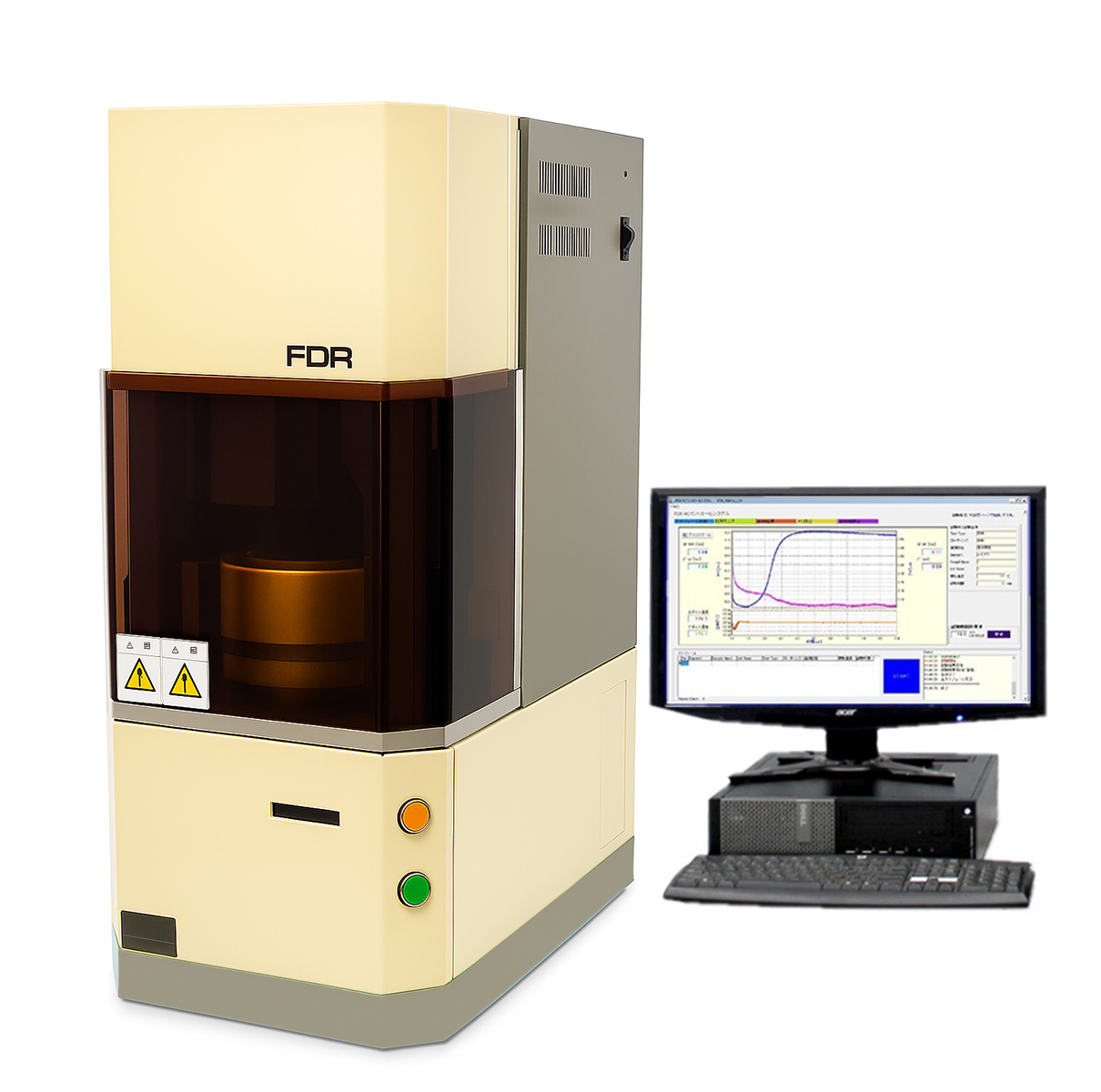

Rotorless curemeter Type Plat Die Rheometer

1. Purpose and Scope

ISO 6502 provides guidance on determining the vulcanization characteristics of rubber compounds using curemeters.

It covers the principles, types of instruments, test procedures, data interpretation, and reporting methods for evaluating the curing (vulcanization) behavior of both natural and synthetic rubbers.

This standard does not specify performance limits but establishes a uniform method for measuring and comparing cure data.

2. Terminology

In addition to the terms in ISO 1382, ISO 6502 defines:

- Oscillating-disc curemeter (ODC): a biconical disc oscillating in a heated cavity containing the test piece.

- Rotorless curemeter (RCM): two dies form a temperature-controlled cavity, one moving relative to the other to apply strain or stress.

- Marching-modulus cure: modulus increases continuously without reaching a maximum.

- Vulcanization characteristics: parameters derived from stiffness–time curves such as minimum torque, scorch time, cure time, and maximum torque.

3. Basic Principles

Rubber stiffness increases as vulcanization progresses.

Curemeters measure stiffness (force or torque) versus time at a constant temperature to produce a vulcanization curve.

From this curve, key parameters are obtained:

- Minimum torque (ML): stiffness of uncured compound.

- Scorch time (tsx): time to incipient cure (processing safety).

- Optimum cure time (t’c90): time to 90% of full cure.

- Maximum torque (MH): stiffness of fully cured rubber.

- Cure rate index (CRI): 100 / (t’c90 – ts2).

These parameters describe the rate and extent of crosslinking in the compound.

4. Types of Curemeters

Three principal designs:

- Oscillating-disc curemeter (ODR) – most widely used historically.

- Reciprocating-paddle curemeter – now largely obsolete.

- Rotorless curemeter (MDR) – newer, faster temperature stabilization, better uniformity.

- Subtypes: reciprocating (linear strain), oscillating unsealed, and oscillating sealed cavity.

5. Apparatus Requirements

A curemeter includes:

- Two heated dies forming a cavity,

- Means to oscillate a rotor or die,

- Sensors to measure torque or force,

- Temperature control and data recording systems.

Key requirements:

- Die material hardness ≥ 50 HRC.

- Temperature accuracy ±0.3 °C; uniformity across cavity within ±1 °C.

- Oscillation frequency 0.05–2 Hz (typically 1.7 Hz).

- Amplitude: ±1° (ODR) or ±0.1°–2° (MDR).

- Torque measurement accuracy ±1%.

Calibration and periodic checks with standard rubber compounds are required.

6. Test Pieces and Conditioning

- Test pieces must be homogeneous, air-free, and slightly larger than cavity volume.

- Condition samples at 23 °C ± 5 °C for at least 3 h before testing.

- Typical test temperature range: 100–200 °C depending on compound type.

7. Test Procedure

- Heat dies to the set temperature and stabilize.

- Insert test piece quickly (within 20 s) and close dies under pressure.

- Start oscillation immediately and record torque vs. time until vulcanization is complete.

- Remove test piece, clean dies if needed, and continue testing further samples.

Protective films (e.g., polyester ≤0.03 mm) may be used to prevent contamination.

8. Expression and Calculation of Results

Derived from the cure curve:

- ts2 or ts5: scorch time (2% or 5% increase over ML).

- t’c(10), t’c(50), t’c(90): time to 10%, 50%, and 90% cure.

- CRI = 100 / (t’c90 – ts2).

Times in minutes, torque in N·m or N.

Results should be expressed as the mean of at least two consistent tests.

9. Test Report Requirements

Must include:

- Reference to ISO 6502.

- Sample description and preparation method.

- Curemeter type, amplitude, frequency, temperature, torque range.

- Heating-up time and test date.

- Recorded cure curve and calculated parameters (ML, MH, ts2, t’c90, CRI, etc.).

10. Informative Annexes

- Annex A: Effect of thermal parameters — discusses deviations from isothermal conditions, heat transfer, and the impact of temperature gradients on cure results.

- Annex B: Refers to ISO 3417 for specific requirements of oscillating-disc curemeters.

- Annex C: Specifies additional requirements for rotorless curemeters (die volume ≤ 5 cm³, temperature stabilization within 1.5 min, and uniformity ± 1 °C).

11. Significance

ISO 6502 provides the fundamental reference for measuring vulcanization characteristics of rubber compounds.

It ensures:

- Reproducibility between laboratories,

- Consistent evaluation of curing systems,

- Reliable data for process control, quality assurance, and R&D applications.

It also serves as the technical foundation for later standards, including ISO 6502-1, -2, and -3, which specify detailed test methods for oscillating-disc and rotorless curemeters.

Bình luận

Fanpage