Product List

Product Search

Featured Products

Featured News

Online support

Tel: 0908866933 - secovina@vnn.vn

Supercritical Fluid Systems

Thống kê truy cập

- Đang online 0

- Hôm nay 0

- Hôm qua 0

- Trong tuần 0

- Trong tháng 0

- Tổng cộng 0

1 x 100L Liter Supercritical Fluid System

SFC

Applied Separations

12 months

Applied Separations, Inc. offers SCF systems in any size and configuration. Although the size of a pilot system versus a production system is arbitrary, customarily, Applied Separations designates pilot systems as having extraction/reaction vessels from 5 liters to 100 liters. Greater than 80 liters, we consider production scale.

Bình luận

Sản phẩm cùng loại

Freeze Drying Plant Sublimator 50

Freeze Drying Plant Sublimator 50 with 2.4m² shelves, -50°C condenser, 25kg ice capacity

Schaller RH2 Portable water activity meter

Schaller RH2 water activity is meter Portable laboratory instrument for determination of water activity (aw value) of food with datalog function. Suitable for measuring materials like butter, fruit mix, spices, granulate, mushrooms, xylit, flour, biscuits or sausage as well as all other food types requiring a check of the water activity value. Furthermore, the humimeter RH2 is suited for measuring special material, e.g. plastic granulate or for climatic and environmental applications.

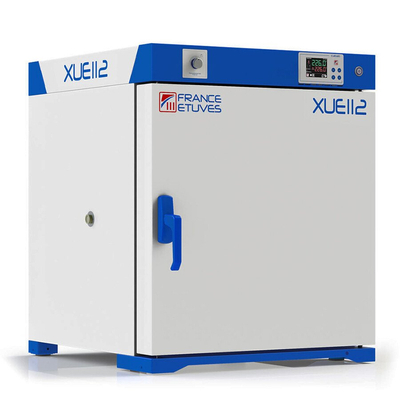

Lab Oven

The FRANCE ETUVES XU universal ovens are suitable for all applications for drying, heating, heat preservation, sterilization, component aging, curing or any other thermal test in laboratories and in all sectors of industry. There are 8 standard volumes : 32 liters, 58 liters, 112 liters, 225 liters, 343 liters, 490 liters, 686 liters and 980 liters. A forced convection for an amazing temperature homogeneity.

Laboratory Vacuum Oven

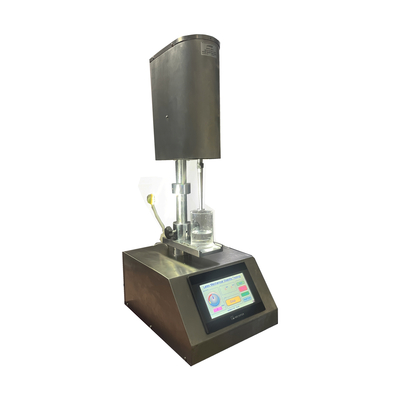

Spray Dryer

BII-S151 Spray Dryer The Lab Spray Dryer can convert liquid solution into dry powder automatically in a timely and safely manner. It has many outstanding features including high efficiency, high recovery, minimal sample destruction and loss, easy configuration, simple operation, and continuous drying process. These excellent features greatly extend the potential application fields that are possible with a spray drying process. The material that can be effeciently processed include but not limite