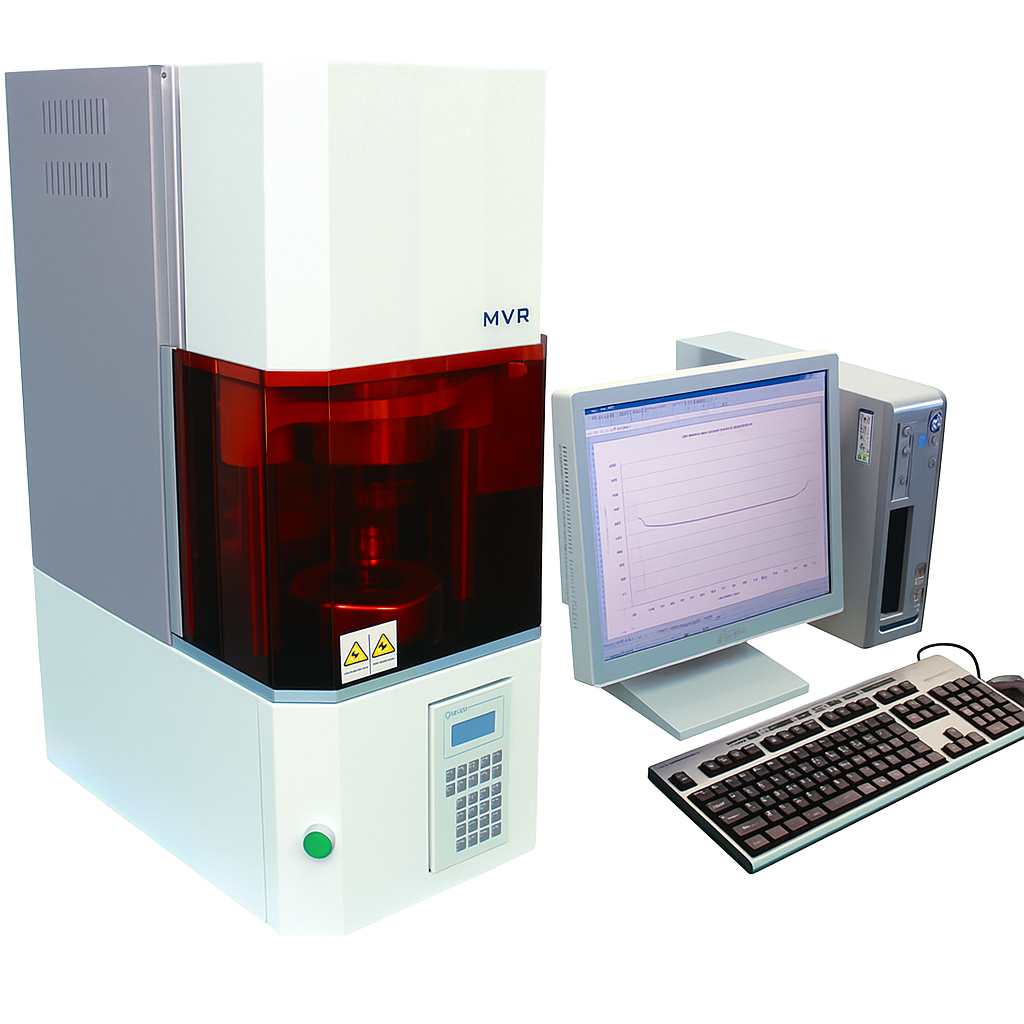

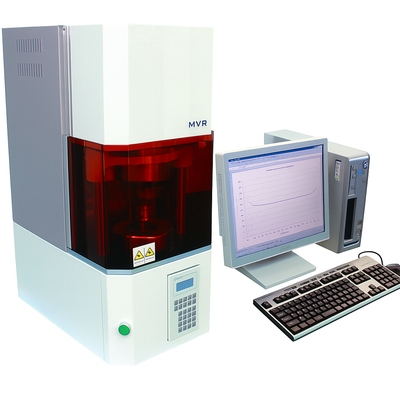

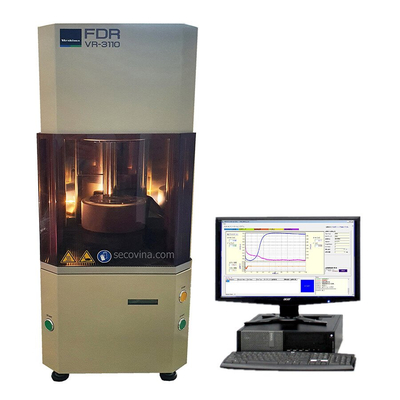

Mooney Viscometer

VR-1130

Ueshima

12 months

Ueshima Seisakusho VR-1130 Mooney Viscometer ●Measurement of Mooney viscosity for unvulcanized rubber ●Measurement of scorch time for unvulcanized rubber Applied Standard JIS K 6300-1, ISO289, ASTM D 1646

secovina@vnn.vn

HOTLINE TƯ VẤN : 0908866933

Specification:

|

Name |

MVR(Mooney Viscosity and Relaxation Tester) |

|

Model |

VR-1130 |

|

Shape of Die |

Radiation V Shape Die (Option: Square Shape Die) |

|

Pressure method |

Pneumatic Cylinder |

|

Rotation speed |

2±0.02rpm |

|

Torque Detector |

Torque cell |

|

Mooney viscosity measuring range |

0.1 ~ 400M(33.2N・m), Display up to 0.1M |

|

Temperature setting range |

Room temp.+5 ~ 200°C, Accuracy ±0.3°C |

|

Table shows LCD |

LCD is 4 rows X 16 columns 、indictable with alphanumeric As soon as the upper and lower dice are closed the testing starts automatically. At the same time, Mooney viscosity, Elapsed Time, Die Temperature are displayed on LCD with digital. Menu button is mainly to select the conditions, function, and display of setting conditions for testing: ①[AUTO/MANUAL]: Change over the test start standby mode and conditions input mode. ②[CAL] : 0 Calibration, Electric Calibration ③[INIT] : Set various kinds of initial setting of the equipment. ④[MODE] : Change over the test mode of MOONEY:SCORCH:RELAX’N ⑤[RESULT] : Display the test result after the testing completion. ⑥[TEMP] : Set and display the temperature conditions. ⑦[PRE] : Set and display the preheating time. ⑧[MOONEY] : Set and display the MOONEY time. ⑨[SCORCH] : Set and display the SCORCH1、SCORCH2 value. ⑩[AFTER] : Set and display the Pressure elimination time. ⑪[RELAX’N] : Used for the case of Multistep relaxing test(VR-1132) ⑫[PRINT] : Used for the case of attaching option |

|

Heating method |

Film heater, PID control with Pt100, 3 pieces |

|

Time |

Preheating time: 0 ~ 99.9min, Mooney measuring time: 0 ~ 99.9min, Pressure elimination time: 0 ~ 99.9min, Scorch display time: 1~99.9min. (Max. 2 conditions working-out), Damping time (VR-1132) on the 0.1 sec. time scale display |

|

Test chamber Door |

Acrylic plastic door |

|

Safety control function |

|

|

Communication |

RS232C |

|

Utility |

(1) Power Source: AC100V/220V, 50/60Hz, Single phase 1.1kVA (2) Compressed Air 0.49MPa |

|

Environmental Condition |

(1)Temperature : 5~40℃, (2) Humidity: 35~80%RH (no dew condensation) |

|

Dimension/Weight |

Approx. 333(W)×530(D)×780(H)mm 105kg |

|

Standard items |

(1) MVR 1 set, (2) Accessories 1set (PC software, special tools and calibration kit) |

Bình luận

Sản phẩm cùng loại

Rotorless rheometer (Flat Die Rheometer)

GEHMAN’S TORSION TESTER

Rubber Two Roll Mill

Geer's Aging Oven

DIN Abrasion Tester

AB-1511

rubber carbon black dispersion tester

Wallace Rapid Plastimeter

Rubber Aging Oven

4386 Bench Top Laboratory Manual Press with Electrically Heated Platens

United Deluxe 2.5KN Table Top UTM

5KN Universal Testing Machine

DEMATTIA FLEX CRACKING TESTER

Hardness Tester (Type A, D)

Compression density tester

Chareontut PR1D-W300L350 PM

Chareontut Internal Mixer

Chareontut Single-Screw Extruder

DIN Abrasion Tester

Flexometer

Fanpage