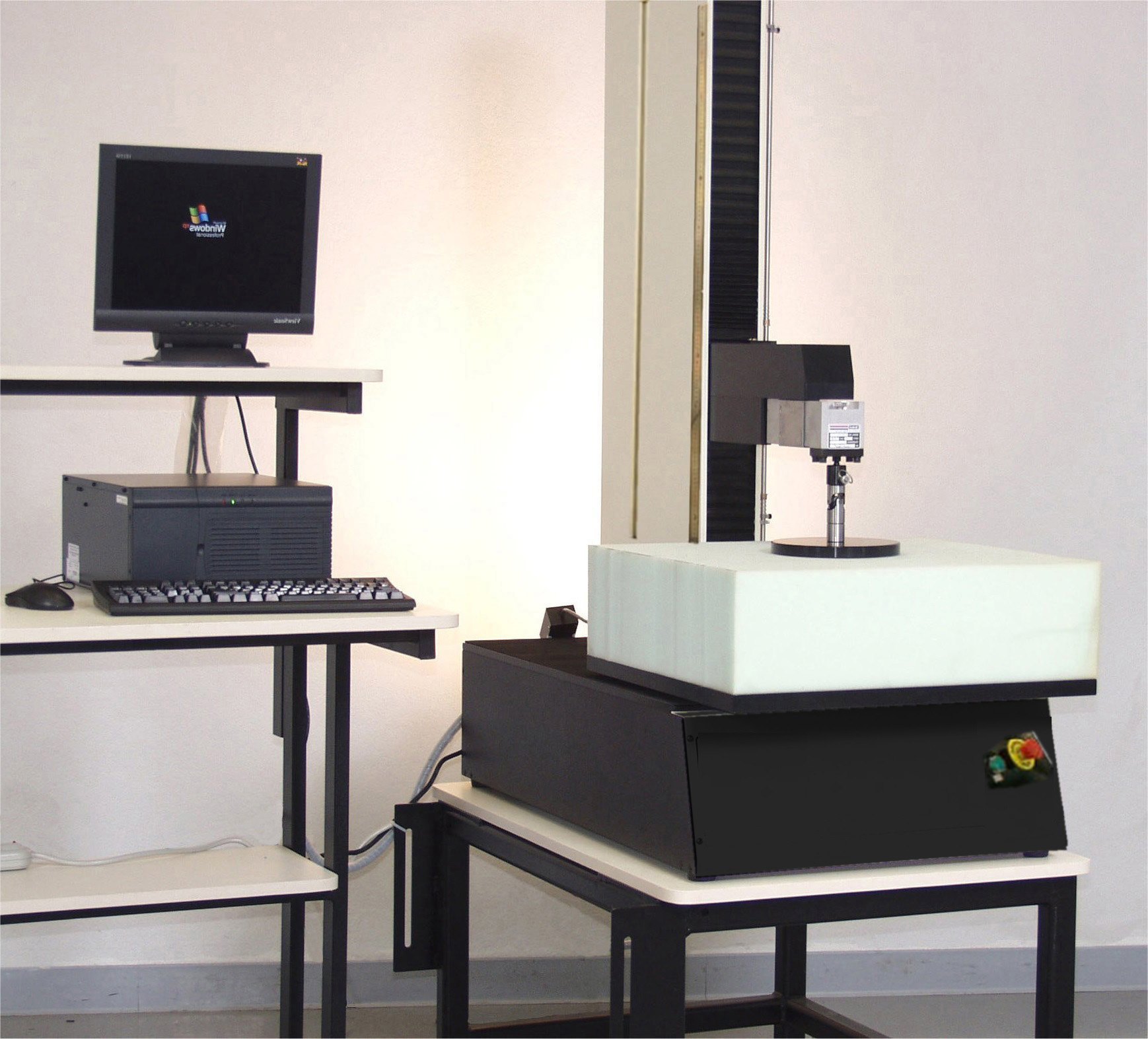

Máy kiểm tra nén Foam

S1

China

12 tháng

Máy kiểm tra nén Foam một cột Model: S1 sử dụng để thử nén Foam theo ASTM D 3574 và ASTM D 5672. Còn được gọi là Foam testing Machine, Máy kiểm tra nén nệm, máy thử nén nệm...

E-mail: secovina@vnn.vn, Zalo: 0908866933

HOTLINE TƯ VẤN : 0908866933

Thử nén Foam, nệm theo:

Testing Method According to ASTM D 3574-03

If the foam is 4" thick or less, use D3574 for testing 25% IFD.

D-3574 Test B1 describes the following steps...

(1) Find the top of the foam; measure the thickness with pressure of 4.5N(1lb).

(2) Preflex 75%. (Speed: :250±25 mm/min)

(3) Return to the top of the foam.

(4) Preflex 75%. (Speed: :250±25 mm/min)

(5) Return to the top of the foam; mark the press location on the foam.

(6) Wait 6 minutes for the foam to relax.

(7) Find the top of the foam; measure the thickness with pressure of 4.5N(1lb).

(8) Compress 25% of the recorded thickness. (Speed::50±5 mm/min)

(9) Wait one minute (while foam is compressed).

(10) Take IFD reading (25% IFD)

(11) Compress 65% of the recorded thickness. (Speed::50±5 mm/min)

(12) Wait one minute (while foam is compressed).

(13) Take IFD reading (65% IFD)

(14) Return to 25% position. (Speed::50±5 mm/min)

(15) Wait one minute (while foam is compressed).

(16) Take IFD reading (2'nd 25% IFD)

(17) Return to top of foam, and remove cushion.

For normal production monitoring of <=4" foam, use ASTM D3574 Steps.

Measurement of specimen: 400mm×400mm×100mm.

The minimum measurement of specimen: 380mm×380mm×100mm.

For normal production monitoring of >4" foam, use ASTM D5672 and modify the steps as it specifies.

For certification testing, use Steps 1-17. Actually steps 14-16 is not listed in that standard,

but it is considered part of the test so that Hysteresis can be computed.

The most important numbers from these tests are:

25% IFD is simply the value from step 10.

Support factor is simply the ratio of step 13 divided by step 10. This is 65%/25%. The higher this number is, the better.

Hysteresis is simply the % loss of step 16 from step 10. This is (step 16-step 10) / (step 10).

The closer to zero this number is, the better. It will always be negative.

The Ashley Bump test is a modification of Steps 1-10, and step 17. It is used in Ashley to test production-sized cushions.

Testing Method According to ASTM D 5672-03

D5672 is used for testing 25% IFD on foam that is thicker than 4".

D-5672 describes the following steps...

(1) Find the top of the foam; measure the thickness with pressure of 4.5N(1lb).

(2) Preflex 75mm(3 inch). (Speed: :250±25 mm/min)

(3) Return to the top of the foam.

(4) Preflex 75mm(3 inch). (Speed: :250±25 mm/min)

(5) Return to the top of the foam; mark the press location on the foam.

(6) Wait 6 minutes for the foam to relax.

(7) Find the top of the foam; measure the thickness with pressure of 4.5N(1lb).

(8) Compress 25mm(1 inch). (Speed::50±5 mm/min)

(9) Wait one minute (while foam is compressed).

(10) Take IFD reading (25% IFD)

(11) Compress 65mm(2.6inch). (Speed::50±5 mm/min)

(12) Wait one minute (while foam is compressed).

(13) Take IFD reading (65% IFD)

(14) Return to 25mm(1 inch) position. (Speed::50±5 mm/min)

(15) Wait one minute (while foam is compressed).

(16) Take IFD reading (2'nd 25% IFD)

(17) Return to top of foam, and remove cushion.

For normal production monitoring of >4" foam, use ASTM D5672 as above steps.

For normal production monitoring of <=4" foam, use ASTM D3574 Steps 1-10, and step 17.

For certification testing, use Steps 1-17. Actually steps 14-16 is not listed in that standard,

but it is considered part of the test so that Hysteresis can be computed.

The most important numbers from these tests are:

25% IFD is simply the value from step 10.

Support factor is simply the ratio of step 13 divided by step 10. This is 65%/25%. The higher this number is, the better.

Hysteresis is simply the % loss of step 16 from step 10. This is (step 16-step 10) / (step 10).

The closer to zero this number is, the better. It will always be negative.

The Ashley Bump test is a modification of Steps 1-10, and step 17. It is used in Ashley to test production-sized cushions.

Bình luận

Sản phẩm cùng loại

Kết nối với chúng tôi