Product

Tìm kiếm sản phẩm

Outstanding product

HOT News

Applied Separations

Online support

Tel: 0908866933 - secovina@vnn.vn

Thống kê truy cập

- Đang online 0

- Hôm nay 0

- Hôm qua 0

- Trong tuần 0

- Trong tháng 0

- Tổng cộng 0

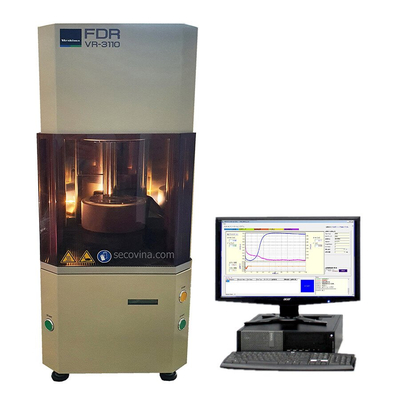

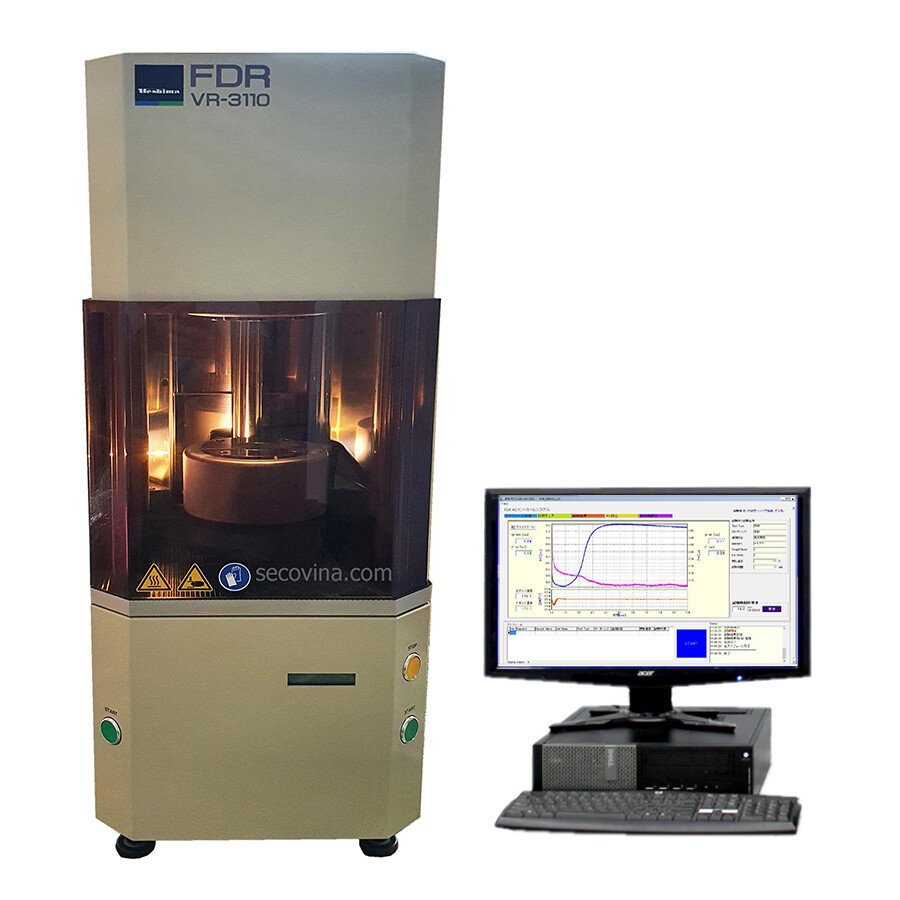

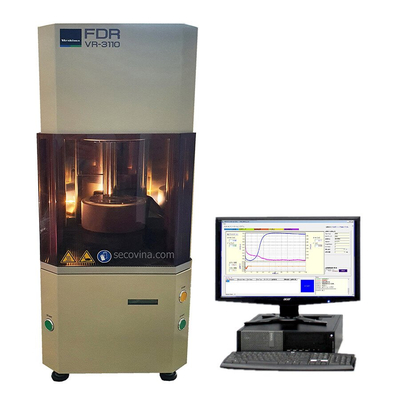

Rotorless rheometer (Flat Die Rheometer)

VR-3110 Series

Ueshima

12 months

|

Name |

FDR(Flat Die Rheometer) |

|

Model |

VR-3110 |

|

Shape of Die |

No friction flat sealed cavity(JIS K 6300-2, ISO 6502, ASTM D 5289 compliant) |

|

Pressurizing Method |

Pneumatic Cylinder (Oil-less type) Cylinder Inner Diameter: 160mm |

|

Oscillation Drive Method |

Sinusoidal Vibration Mechanism by Conical Rotational Motion “Cone Drive” |

|

Oscillation Drive Motor |

Synchronous Motor 25W AC |

|

Oscillation Transmitting Method |

Elastic Connection by Leaf Spring |

|

Frequency |

1.67Hz (100cpm) |

|

Oscillation Angle |

±1° |

|

Oscillation Angle Accuracy |

2±0.03°(Without Load) |

|

Torque Detecting Method |

Strain Gauge Type Load Cell |

|

Torque Transmission Method |

Elastic Connection by Leaf Spring |

|

Testing Temperature Range |

50 to 230° C |

|

Temperature Control Accuracy |

Die Temperature: ±0.3° C at 190° C Internal and External Die Temperature Difference: ±1.0° C at 190° C |

|

Heat Control Method |

Independent PID Control on four pieces of Film Heaters (Upper / Lower Die, Upper Outer / Lower Outer Die) |

|

Temperature Sensor |

Platinum Resistance Sensor (Pt100) 4pcs |

|

Maximum Testing Time |

9999minutes |

|

Shield Cover |

Colored Acrylic on Front and Sides (Preventing external air and for Safety) |

|

Safety Equipment |

(1) Two-hand Press Start Switch (Cylinder lifts only when both buttons are pressed simultaneously.) (2) Overload Protection (more than 22N・m) (3) Overheat Protection (Heater will be turned off at 240° C or higher.) |

|

Communications |

RS232C |

|

Utilities |

(1) Power Source AC100V/220V, Single Phase, Power Consumption less than 700VA (2) Dry Air 0.343 to 0.686MPa |

|

Environmental Conditions |

(1) Temperature 5 to 40° C (2) Humidity 35 to 80%RH (No Dew Condensation) |

|

Dimensions and Weight |

Approx.333(W)×520(D)×780(H)mm, Approx.110kg |

|

Standard Items |

(1) Equipment main unit: 1 set (2) Accessories 1set (Software, Special Tool, Minimum Consumable Parts etc.) |

Option:

●Sponging Pressure Measurement

[Application] It is useful for research/development and production line control on sponge rubber to examine

sponging pressure and relationship between blowing agent reaction and vulcanization of sponge rubber.

●Programmable Temperature Control

[Application] It simulates vulcanization of large sized rubber products, continuous vulcanization, mold vulcanization, etc. to examine vulcanization characteristics with rising temperature at a preset temperature rise.

Bình luận

Sản phẩm cùng loại

Mooney Viscometer

GEHMAN’S TORSION TESTER

GAS PERMEABILITY TESTER

Geer's Aging Oven

DIN Abrasion Tester

The DIN Abrasion Tester is of the type that rotates a drum with grinding cloth wound around the surface at a specified speed, presses the sample against the grinding cloth. Applicable Standard: JIS K 6254-2/ISO4649/ISO23794 Test Piece Size: 16.2±0.2mm dia, 6mm or thicker Drum Size: 150±0.2mm dia., 460mm wide Drum Speed: 40±1rpm