Constant-stress/strain flexometer

FT-1250

Japan

12 months

Rubber, vulcanized — Determination of temperature rise and resistance to fatigue in flexometer testing: Constant-stress/strain flexometer. This machine determines change in complex modulus of elasticity E', E", tan6 and heating rate of rubber during the thermal fatigue process. Standard: ISO 4666, JIS K 6265,...

secovina@vnn.vn

HOTLINE TƯ VẤN : 0908866933

Ueshima Constant-stress/strain flexometer Model FT-1250

1. INTRODUCTION

This machine determines change in complex modulus of elasticity E', E", tan6 and heating rate of rubber during the thermal fatigue process.

It employs hydraulic servo mechanism in the drive system and in addition to measurement based on constant strain of the conventional Flexometer (Goodrich Flexometer) it also allows measurement based on constant load (constant stress).

It incorporates a needle type thermocouple (temperature sensor) for detecting sample's temperature.

Temperature in the center of sample is determined by inserting the needle thermocouple into the sample

The data of tanδ, E', E" and creep are displayed in the form of graph on the personal computer's screen while conducting measurement, allowing you to monitor the measuring process.

SPECIFICATIONS

Standard: ISO 4666/JIS K 6265

Type: Compression Flexometer

Test piece:

(1 )Shape : Cylindrical

(2 )Dimensions:φ 30.0× 25mm、φ 17.8× 25mm(Option for FT-1250)

Preloading :

(1 )Method : By hydraulic cylinder with servo control

(2 )Load : 50 to 500N

Dynamic Loading:

(1 )Method : By hydraulic cylinder with servo control

(2 )Mode : (A)Constant strain amplitude(B)Constant stress amplitude

(3 )Amplitude: (A)1 to 6.5mmp-p (B)50 to 1500Np-p

Load Detector: 5000N rating load cell

Displacement Detector: 20mm stroke differential transformer

Frequency: 5 to 50Hz

Temperature Range of Thermostat Chamber: 50 to 150℃(50 to 100℃±1℃、 100 to 150℃±3℃)

Measuring of Testpiece Temperature: By a needle type thermocouple continually position-controlled at the center of the interior of the testpiece

Testpiece Supply: One testpiece, manual operation one by one

Measurement:

(1)Output Data

(a) Temperature of testpiece

(b) Creep

(c) Visco-elastic parameters:

・ Storage modulus(E’)

・ Loss modulus(E’’)

・ Loss factor(tanδ )

(2)Indication: Graphic display

Electric Supply:

Main part of Flexometer: Single phase AC220V15A

Hydraulic power Unit: 3-phase AC 380V 25A

Cooling water Requirement for Hydralic Power Unit:

Temperature :Lower than 28℃、

Flow rate : 20ℓ/min

Dimensions Main part of Flexometer: 750(W)× 835(D)×1470(H)mm

Bình luận

Sản phẩm cùng loại

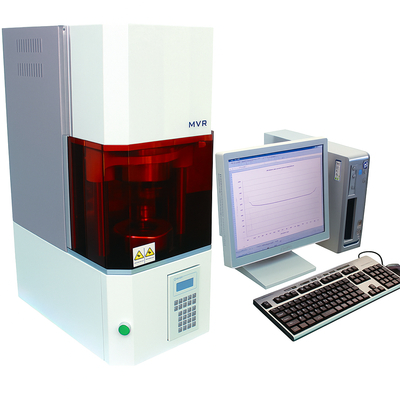

Mooney Viscometer

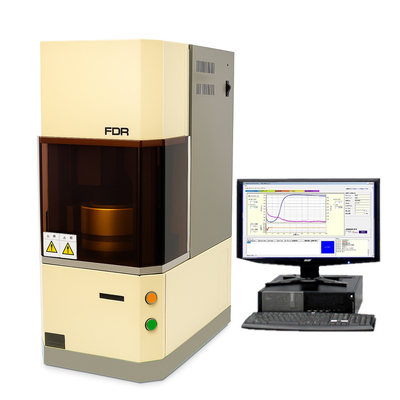

Flat Die Rheometer (FDR)

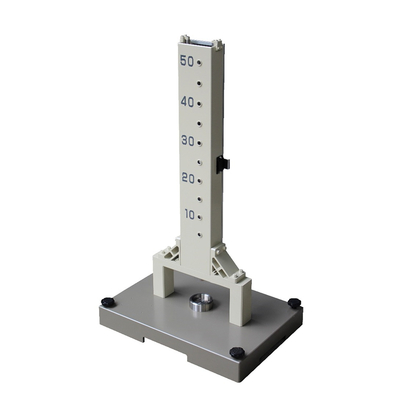

Dynamic Mechanical Analyzer (DMA)

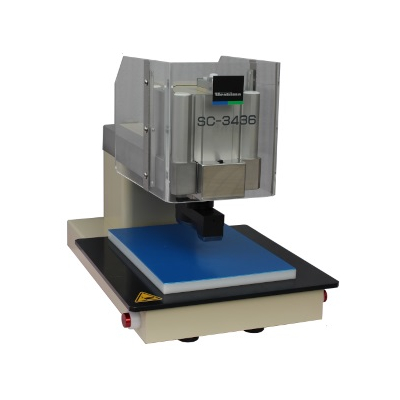

Maron Type Mechanical Stability Tester

VR-6155

AB-1150 LAMBOURN ABRASION TESTER

FPS WEAR TESTING SYSTEM

TR Tester

Akron Abrasion Tester

Dupont Impact Tester

GEHMAN’S TORSION TESTER

Cable Abrasion Tester

Durometer Shore A - Shore D

Low Temperature Brittleness Tester

RTM Friction Tester (Tire)

latex mechanical stability tester

GEER’S AGING OVEN

Tensile testing machine

Pneumatic Drive Press Cutting Machine

Akron Abrasion Tester

DIN Abrasion Tester

DEMATTIA FLEX CRACKING TESTER

Fanpage