SCCO2 5L Extraction Equipment

SE-051 series

TST - Taiwan

12 months

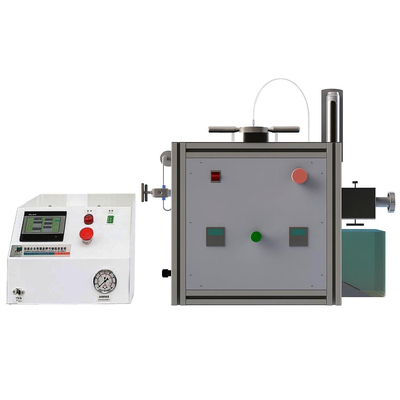

SE-051 Series Supercritical CO2 System Custom 5L System (SCCO2 5L Extraction Equipment)

secovina@vnn.vn

HOTLINE TƯ VẤN : 0908866933

Product Specification

SE-051CSR Supercritical CO₂ 5L Extraction Equipment

– with CO₂ recycling system

1. System Requirement (Supplied by Buyer)

1-1. Electricity: 220V / 30A / 3-PH / 50Hz

1-2. Compressed air: 7~8 Kgf/cm²; 6.6 m³/min

1-3. Equipment size (reference): (L)2100mm × (D)1300mm × (H)1900mm

2. System Specification

2-1. Maximum extracting pressure: 500 bar

2-2. Maximum extracting temperature: 80°C

3. System Main Units

3-1. Extraction tank: 6L × 1

3-1-1. Maximum pressure: 500 bar

3-1-2. Maximum temperature: 80°C

3-1-3. Extraction basket: 5L × 1

3-2. Separation tank I: 2.5L × 1

3-2-1. Maximum pressure: 180 bar

3-2-2. Maximum temperature: 80°C

3-3. Separation tank II: 2L × 1

3-3-1. Maximum pressure: 80 bar

3-3-2. Maximum temperature: 80°C

3-4. LCO₂ storage tank: 12L × 1

3-4-1. Maximum pressure: 90 bar

3-5. CO₂ pump: 1 Kg·CO₂/min (max)

3-6. Co-solvent pump: Flow rate 18 ml/min (max)

3-7. Cooling system: Cooling capacity 6KW

3-8. Heating system: Electric heating

3-9. CO₂ recycling system: 70% recycling rate by pressure difference

4. Piping and Structure

4-1. Piping: SUS316 (BA Pipe)

4-2. Material of structure and plate: SUS304

5. Control System and Monitor

5-1. Main control valve: High-pressure manual back pressure valve

5-2. Temperature monitor and control system: 7” color touch panel HMI

5-3. Pressure monitor and control system: 7” color touch panel HMI

5-4. Liquid level monitor: Reflex liquid level gauge

5-5. Program to control temperature, pressure, and time

6. Safety and Protection

6-1. Rupture disk

6-2. Safety relief valve

6-3. Emergency stop button

6-4. Over-pressure auto shutdown

6-5. Jacket insulation protect with the heating part

7. Certifications & Industrial Safety

7-1. TST Supercritical extraction equipment systems meet ASME Sec.VIII, Div.II code design and manufacture of the United States.

7-2. ISO 9001:2015: TST Supercritical extraction equipment of Design, Development, Manufacturing, and Sales are met of Germany’s TÜV Rheinland for ISO 9001:2015 standards approved.

7-3. CE: EN60204-1:2018

15 HP Automatic Air Compressor

(Included Air Storage Barrels) Specification

Model: TST-TA15P

Voltage: 220V / 3 Phase / 50 Hz

Machine Size: 1600 × 700 × 1400 mm

Weight: 480 Kgs

Power: 15 HP

Pressure: 7 kg/cm²

Storage Barrels Material: SS400

Volume: 360L

Transformer Specification

Model: STS-TCC-033

Type: Isolation

Voltage: 380V Transfer to 220V / 3 Phase / 75 A

Machine Size: 52 × 40 × 52.5 cm

Weight: 150 Kgs

Bình luận

Sản phẩm cùng loại

Supercritical Fluid Extraction

Supercritical Fluids Extraction

SE-2000–10000 Series supercritical fluid extraction

20/40 Liters Supercritical Extraction Systems

Ultrasonic 17L Lab Extraction Equipment

Ultrasonic 100L Extraction Equipment

Fanpage