Accelerated Weathering Tester – UV

EQNA UV

Equilam N.A. - USA

12 Months

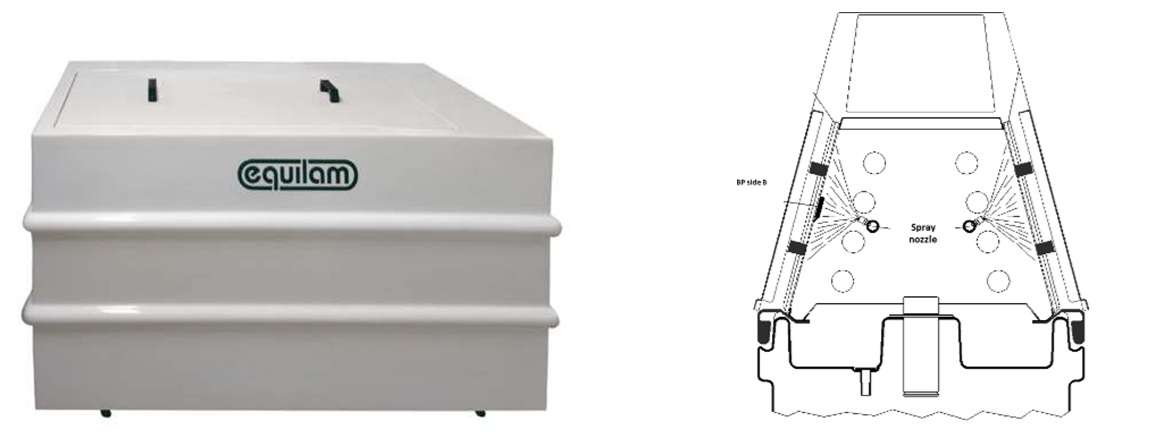

The accelerated weathering test simulates the atmosphere with sunlight (UV mode), dew (condensation mode), rain (thermal shock) and rain + UV (thermal shock and UV). The test results are reliable, fast and comply with the technical standards ASTM D4329, ASTM G154, ASTM G151, ASTM G53, SAE J2020, ISO 4892-3, among others. Contact Us: Email: secovina@vnn.vn OR Mr. Felipe Rojo, Email: frojo@equilamna.com , Phone: 1.754.900.7816 .

secovina@vnn.vn

HOTLINE TƯ VẤN : 0908866933

The accelerated weathering test simulates the atmosphere with sunlight (UV mode), dew (condensation mode), rain (thermal shock) and rain + UV (thermal shock and UV). In a few days or weeks, the EQNA UV tester can reproduce the damage that occurs over months or years in external or internal environments with sunlight. It predicts damage to non-metallic materials (deterioration, aging, erosion, mechanical and physical changes, humidity and shine) and reduces losses. The test results are

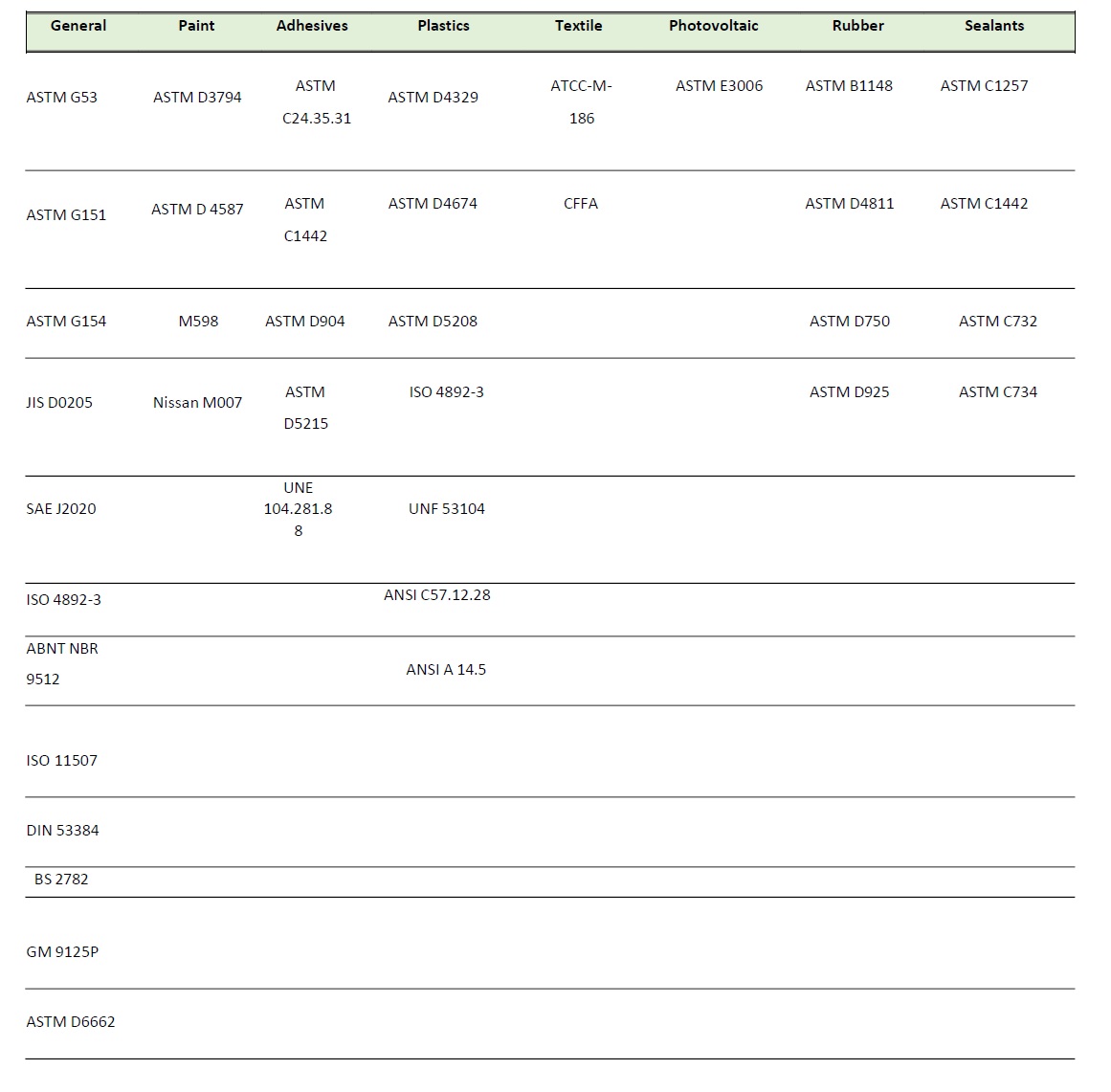

reliable, fast and comply with the technical standards ASTM D4329, ASTM G154, ASTM G151, ASTM G53, SAE J2020, ISO 4892-3, among others.

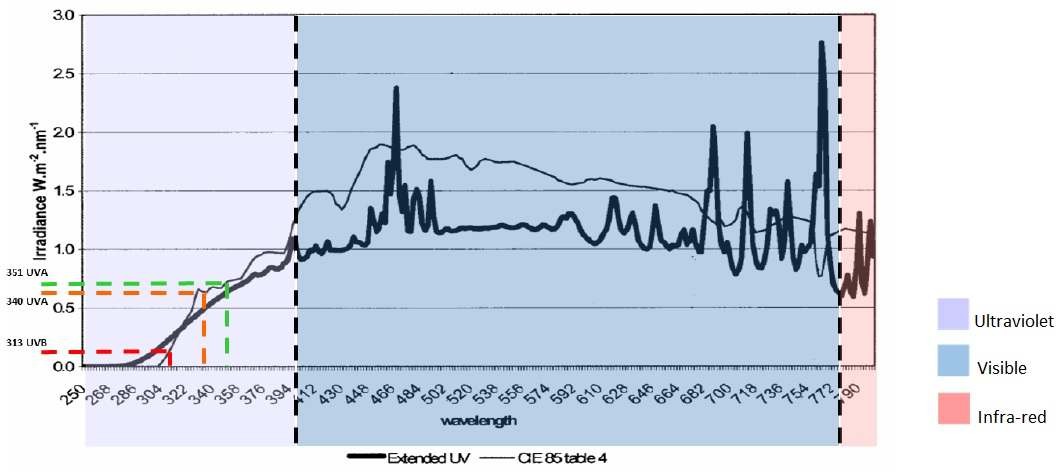

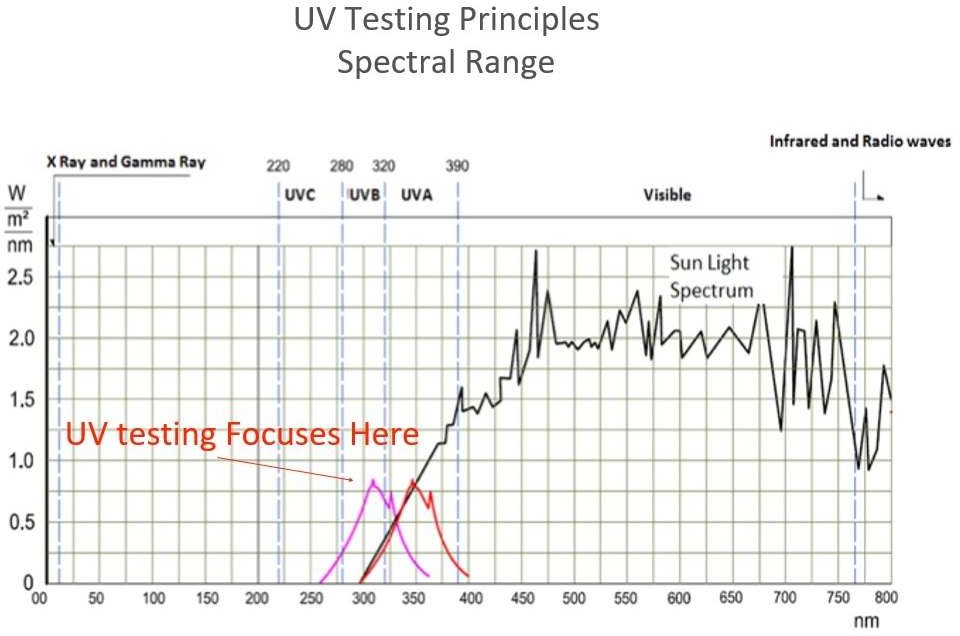

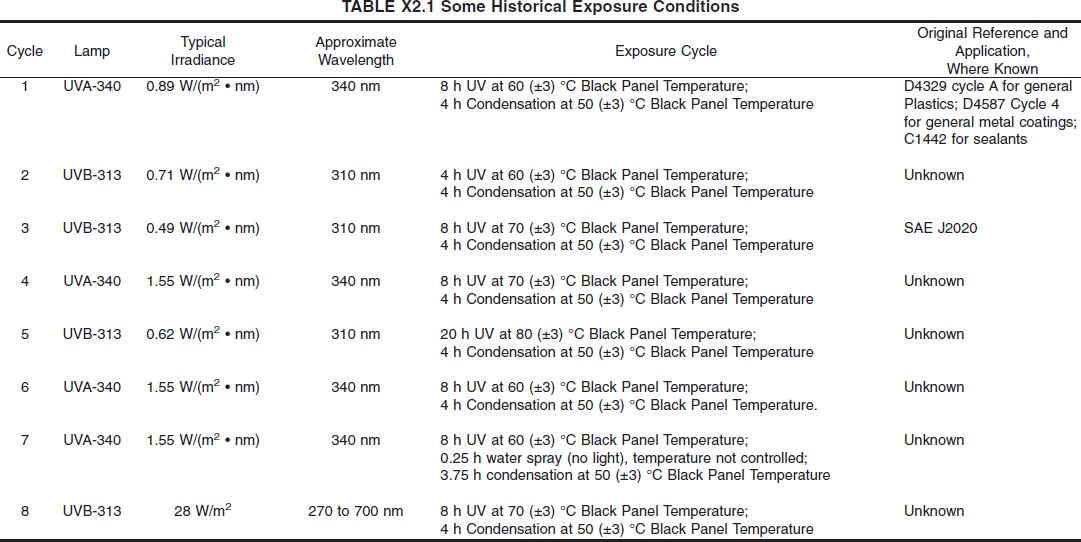

UVa and UVb irradiation together with the action of the weather acts as the main cause of physical/chemical damage in relation to the intensity and wavelength of light in the solar spectrum. According to SAE J2412, the CIE 85 of the solar spectrum collected under natural weather conditions, as shown in the graph below, presents UV irradiation between 250 and 400 nm, visible light between 400 and 780 nm and infrared above 780 nm. When the aging process is accelerated in non-metallic materials, ultraviolet fluorescent lamps within the wavelength range between 290 and 400 nm are used. This wavelength range is more harmful to non-metallic materials, so that the technical standards - Xenon Test (Wheather o meter), recommend the calibration of xenon equipment exactly in this harmful range of the spectrum from 250 to 400 nm. By analyzing the irradiance intensity provided by the solar spectrum collected under natural climatic conditions in relation to the wavelength of 313 nm, approximately 0.15 W/m².nm is obtained, for 340 nm the irradiance is 0.60 W/m².nm and for 351 nm approximately 0.80 W/m².nm of irradiance. To ensure the accelerated action of the range of non- metallic materials, Equilam supplies UVa and UVb fluorescent lamps that guarantee an intensity higher than that of the solar spectrum under natural climatic conditions, optimizing laboratory testing time and strictly meeting the standards of accelerated weathering testing techniques. The evidence and comparisons between laboratory tests and real tests are validated under natural climatic conditions over a longer test period, to effectively prove the safety of the results collected.

Source: Image modified from SAE J2412 EN, 2005.

Application:

The EQNA-UV chamber accelerates the degradation and aging of some non-metallic materials, causing loss of shine and color, mechanical resistance, bubbles, disintegration and oxidation.

The EQNA-UV chamber assists in the development of new materials and in the improvement of existing materials, and is regularly used by industries such as:

-

Automotive Industry

-

Varnishes and Paints

-

Textiles

-

Wood

-

Cosmetics

-

Research Centers

-

Universities

-

Petrochemicals

-

Plastics and Rubber

In the automotive industry in general, support with the use of the Accelerated Weathering Test Chamber stands out, with lamps that emit UV light, which is 290 nm to 400 nm, designed to verify and validate the use of materials, identifying their maximum wear.

PERFORMANCE:

The EQNA UV comes in 3 different models, providing the best to meet the Accelerated Weathering reference standards, highlighting the EQNA UV + Condensation + Spray / UV + Spray (Thermal shock), which meets cycle 7 specified in ASTM G154 standard, among others, comprising high technology with excellent performance, in a controlled and automatic way.

|

Model |

EQNA

|

EQNA

|

EQNA

|

|

MODE UV. |

Included |

Included |

Included |

|

MODE CONDESATION. |

- |

Included |

Included |

|

MODE SPRAY. |

- |

- |

Included |

|

MODE SPRAY/UV. |

- |

- |

Included |

|

Technical standards. |

ASTM G 154, ASTM G 151, SAE J2020, ISO 4892. For others, please contact us |

||

|

Temperature setting – UV Mode. |

Ambient Temp. (+5°C) +9°F to (80°C) +176°F |

||

|

Temperature setting - Condensation mode. |

Ambient Temp. (+5°C) +9°F to (60°C) +140°F |

||

|

Temperature setting – Spray Mode. |

Ambient Temp. |

||

|

Temperature setting – Spray / UV Mode. |

Ambient Temp. (+5°C) +9°F to (80°C) +176°F (UV Mode). Deionized water from the tank that will be used in SPRAY MODE will always be at the lab's ambient temperature. |

||

|

Irradiation units available on the control panel. |

W/m²/nm – W/m² - J/m² - kJ/m²/nm |

||

|

Temperature units available on the control panel. |

°C / °F |

||

|

Uniformity of UV MODE irradiation. |

+/- 4% of sample surface |

||

|

Fully integrated deionized water tank with chamber software. 350 liter (92.5 gal) capacity, SPRAY MODE or UV/SPRAY MODE. |

- |

- |

Optional |

|

Deionized water specification for SPRAY mode. Quality water ASTM D1193 type IV. |

- |

- |

Ø = ¾” Flow: 0,23 CFM (6,5 l/min) / 0,25 CFM (7,0 l/min) Presssure: 0,5 ~ 1,0 bar |

|

|

|

|

Drain: Ø = 1” |

|

Specification of deionized water for condensation mode – Quality water ASTM D1193 type IV. |

- |

Ø = ¼ ” Flow: 0,035 CFH (1,0 l/h) Pressão: 0,5 ~ 1,0 bar Dreno: Ø= 1/2” |

|

|

Tray heating element (condensation mode) in shielded 316 stainless steel. |

Included |

||

|

Automatic water level control in the tray, condensation mode. |

- |

Included |

|

|

Control panel |

7” Color Touch Screen |

||

|

Number of test specimens (ASTM G154) |

48 standard samples of 75 x 150 mm (ASTM G154) and thickness up to 20 mm,+ 2 Black panels |

||

|

“EQNA UV CONTROL SOFTWARE”. UV fluorescent lamps are monitored for radiation consistency during testing, and feature an automatic power compensation system for lamp depreciation without user intervention. Ensuring longer lamp life. |

Included are four (4) fixed UV sensors. One (1) standard UV sensor for calibration. |

||

|

“EQNA UV CAL SOFTWARE” Radiometer integrated with the camera control panel. Calibration/adjustment of fixed sensors and indication of sensor failure. |

Included, One (1) standard UV sensor for calibration/verification. |

||

|

“EQNA TEMP. CAL SOFTWARE” Validation and calibration of temperature sensors (two), integrated (Black Panel). Two Black Panels (side A and side B) – Ensuring temperature uniformity and safety. |

Included |

||

|

Alarm/service messages with a simple touch of the screen. |

Included |

||

|

Self-diagnosis function: Temperature alarm (high and low) and error details. Low water level alarm in the tray and error details. Lack of pressurized water alarm and error details. Lamp irradiation depreciation and control alarm (irradiation power) and error details. |

Included |

||

|

Stores date and time of alarms and preventive maintenance. Test end alarm. |

|

|

20 test programs with 100 segments (4 unlocked programs + 16 password locked programs). |

Included |

|

Timer for each programmed mode |

UV Mode, Condensation Mode, Spray Mode, UV/Spray Mode |

|

Allows you to work with UV fluorescent lamps. |

Uva, Uva+, UVb, UVb+, UVc, UV421 |

|

Supervisory software, data acquisition. |

Optional |

|

Total area of sample exposure. |

6,000 cm2 (4 quadrants of 1500 cm2) |

|

UV intensity uniformity area. |

21 x 90 cm / Total area = 1890 cm2, According to SAE J 2020 (Fig.3) |

|

Maximum irradiation 340 and 351 nm (UVa). |

1,70 W/ m2.nm |

|

Maximum irradiance 313 nm (UVb). |

1,25 W/ m2.nm |

|

Condensation mode tray made of polymeric material with protection against UVa and UVb radiation. Eliminates contamination by mineral scaling in the tray, preventing corrosion due to leaks. No need for sacrificial anode. |

Included |

|

Lid opening safety system. |

Automatically when the lid is opened, the heating and UV irradiation functions are turned off and the programming is paused, protecting the operator for safe sample inspections and facilitating maintenance. |

|

Power supply |

208 ~ 240 Volts –1 - 60 Hz – 20 Amps |

|

Automatic restart after power failure. |

If it is the customer's responsibility, the function can be enabled on the equipment's control panel. |

|

Water quality |

ASTM D1193 Type IV |

|

Independent timer for each mode with indication of execution time (S.V) and set value (S.P). |

Included |

|

Total test time timer, with indication of execution time (S.V) and total adjusted value (S.P). |

Included |

|

5 (five) partial test timers, for samples added during the test run. |

Included |

|

Wooden packaging dimensions (W x D x H). |

59.0”x 29.5”x 57.1” (1,500 x 750 x 1,450 mm) |

|

Weight. |

321.9 lbs (146 kg) |

|

External dimensions (W x D x H).

Weight |

55.9”x 26.4”x 53.5” (1,420 x 670 x 1,360 mm)

222.7 lbs (101 kg) |

|

Access Required |

Approximately 39” (1 m) around the equipment |

|

Temperature and relative humidity of the equipment installation environment for better performance. |

+63°F - +82°F (17°C - 28°C) 40% - 85% (without condensation) |

CONSTANT IRRADIATION INTENSITY DURING THE TEST - “EQNA UV CONTROL” SOFTWARE

Efficient and safe, EQNA UV chambers feature "EQNA UV CONTROL" software and an irradiance sensor for each pair of lamps, which controls and monitors the irradiance intensity throughout the test, ensuring constant irradiance uniformity. Increasing lamp life and optimizing lamp costs, all technology is provided directly on a touchscreen with intuitive software.

IRRADIANCE VALIDATION AND CALIBRATION SYSTEM - “EQNA UV CAL” SOFTWARE

Many irradiance calibration technologies prioritize sensors already installed in the chamber which are directly close to the exposure region. However, over time, the dissimilarity between the results collected becomes noticeable after a few years of use, due to the sensors’ aging. With this in mind, Equilam provides the “EQNAUV CAL” software that, through the Radiometer integrated into the equipment’s control panel, promotes communication between the sensors installed in the chamber and the radiometer’s standard external sensor, providing instant calibration of the chamber’s sensors.

The advantages of using the Radiometer are:

-

Consistent results;

-

Easy calibration without the need to move the equipment;

-

Irradiance accuracy;

-

Safe and fast system;

-

Cable communication between the equipment and the calibrator;

Reference in calibration method

EQNA BP CAL SOFTWARE

Efficiently and safely, EQNA UV chambers feature "EQNA BP CAL" software and a standard temperature sensor attached to the black panel where the two chamber temperature sensors (side A and side B) are validated and adjusted, providing excellent homogeneity and safety for your test.

DATA ACQUISITION - SUPERVISORY – OPTIONAL

Export .CVS files of test temperature, irradiance (UV), Condensation, Spray and UV + Spray data to laptop, generating graphs for analysis of test performance.

Fluorescent Lamp Specifications

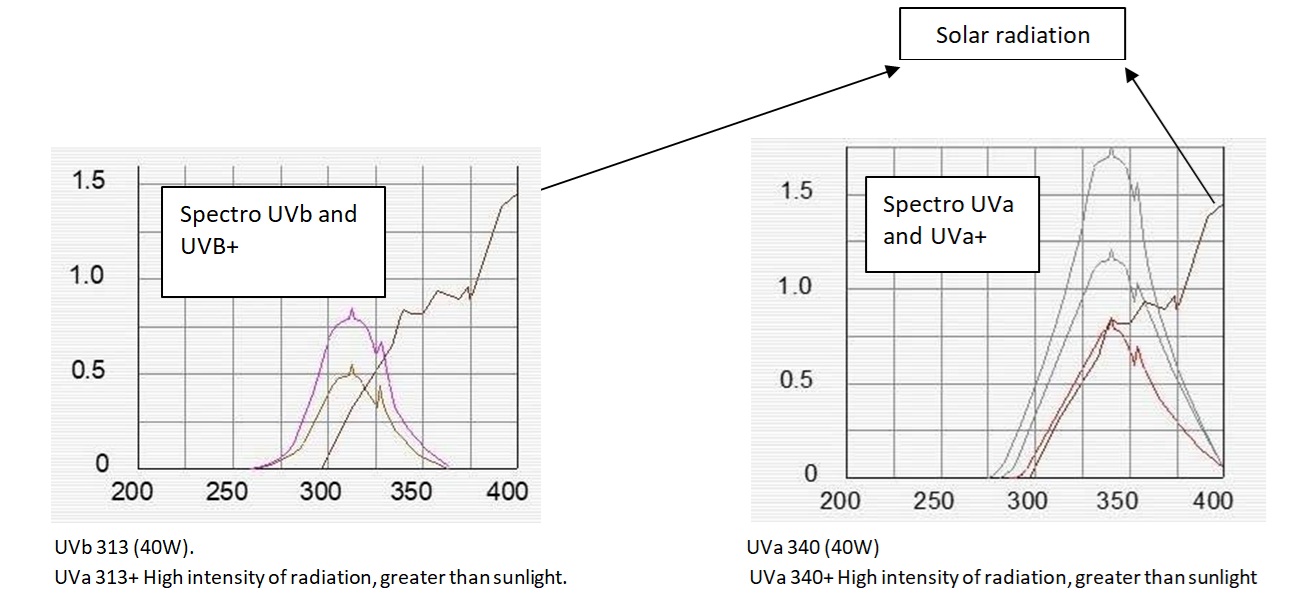

The EQNA UV series works with lamps with wavelengths of 340, 351 and 313, within the irradiance range required by the standards: ASTM G 154, ASTM G 151, ASTM G 53, SAE J 2020, ISO 4892, among others. We also offer lamps with wavelengths of 254 nm (UVc) bactericidal and 421 near solar irradiation between wavelengths 290 to 450 nm.

Bactericidal Lamp: UV light is widely used in ultraviolet germicidal irradiation (UVGI), a technique used to eliminate harmful viruses and bacteria. Short-wavelength, high-energy UVc irradiation can also degrade the materials and surfaces it disinfects. The 254 nm UVc Lamp uses UVc lamps to provide concentrated irradiation at 254 nm to test the durability of the material against the effects of photodegradation resulting from exposure to UVc light.

UV 421 lamp: They offer the same excellent light source match provided by UVA-340 lamps, with proximity to solar irradiation between wavelengths 290 and 450 nm. They also emit long-wavelength UV light and short-wavelength visible light. This extended spectrum can reproduce color change effects in materials susceptible to these wavelengths and can provide a more comprehensive test.

The guarantee of a safe test result is their working range within the lamp spectrum developed by Equilam; if this is met, the result will be consistent with an accelerated time analysis, following technical standards. For further details, please contact us.

|

|

Types of UVA and UVB fluorescent lamps according to ASTM G154 |

|||||

|

340 (40 W) |

340 + |

351 (40 W) |

351 + |

313 (40 W) |

313 + |

|

|

Maximum irradiation intensity of the lamps (W/m².nm). |

1,05 |

2,02 |

1,73 |

2,35 |

1,25 |

1,50 |

|

Maximum irradiation intensity * ASTM G 154 (W/m².nm). |

1,55 |

1,55 |

1,55 |

1,55 |

0,71 |

0,71 |

|

Representative irradiation intensity* ASTM G 154 (W/m2.nm) |

0,89 |

0,89 |

0,89 |

0,89 |

0,49 |

0,49 |

* The representative and maximum irradiation intensity values used above can be considered in accordance with a wide range of technical standards for accelerated weathering by UVa and UVb fluorescent lamps.

Durability of lamps 340+, 351+ and 313+:

- By monitoring the “EQNA UV CONTROL” software, with adjustment of the set point of the maximum irradiation intensity supported by the lamps in continuous use, the useful life will be approximately 750 hours.

- By monitoring the “EQNA UV CONTROL” software, with adjustment of the set point of the maximum irradiation intensity ASTM G154 in continuous use, the useful life will be approximately 1,500 hours.

- By monitoring the “EQNA UV CONTROL” software, with adjustment of the set point of the typical irradiation intensity ASTM G 154 in continuous use, the useful life will be approximately 8,000 hours. The values in bold above are not guaranteed, as there are external factors that can change them.

UVb 313 (40W). UVa 340 (40W)

UVa 313+ High intensity of radiation, greater than sunlight. UVa 340+ High intensity of radiation, greater than sunlight

Deionized Water Tank - Spray or UV/Spray Mode

Spray or UV Spray Mode: We recommend an ASTM D1193 type IV deionized water tank, as the test standards do not allow the reuse of this water (See ASTM, ISO). The Equilam EQNA UV Chambers have a 350-liter tank for receiving deionized water, fully integrated into the chamber software, with simple operation on the touch screen panel.

We recommend that the DEIONIZED water used during Spray mode be disposed of along with possible contaminants that may interfere with the test results, ensuring that there is no recirculation of contaminated DEIONIZED water, following ASTM G154 / ASTM G 151 / ISO 4892-3 standards.

Optional accessories:

|

EQOP.0005 |

Special fixture, in accordance with customer specifications |

|

EQOP. 0013 |

DEI Water – ASTM D 1193 Type IV |

|

EQOP. 0027 |

Wood crate |

|

EQOP. 0036 |

Equipment’s Certificate – Temperature and Irradiance |

|

EQOP. 0037 |

Supervisory software, data acquisition. Export .CVS files of test temperature, irradiance (UV), Condensation, Spray and UV + Spray data to laptop, generating graphs for analysis of test performance. |

|

EQOP. 0048 |

UVb 313 Lamps (40W) – box with 12 |

|

EQOP. 0049 |

UVa 340 Lamps (40W) – box with 12 lamps |

|

EQOP. 0050 |

UVa 351 Lamps (40W) – box with 12 lamps |

|

EQOP. 0162 |

UVb 313 + Lamps – (high intensity of irradiance) - Box with 12 lamps |

|

EQOP. 0057 |

UVa 340 + Lamps - (high intensity of irradiance) - Box with 12 lamps |

|

EQOP. 0058 |

UVa 351 + Lamps - (high intensity of irradiance) - Box with 12 lamps |

|

EQOP. 0060 |

UVc – Bactericidal Lamp - Box with 12 lamps |

|

EQOP. 0061 |

UV 421 - Box with 12 lamps |

|

EQOP. 0164 |

Support 3D – For samples in three dimensions. W x D x H : 19 ,68 ” X 13 , 78 ” X 2,75”. |

|

EQOP. 0165 |

Support 3D – For samples in three dimensions. W x D x H: 19 ,68” X 13 , 78 ” X 5,90”. |

|

EQOP. 0051 |

Tank with DI water pressurization for Spray MODE. Software and pump included. Ext. Dim. W x D x H: 66.9” x 35.4” x 37.8”. Tank Volume 100 gal (380L). Weight Net: 176 lbs. (80 Kg) |

Optional – 3D sample support

3D support, with the possibility of testing parts with depths of up to 70 mm or 150 mm, ease of work, and analyses on samples with three dimensions.

Bình luận

Sản phẩm cùng loại

Salt Spray (Salt Fog)

Cyclic Corrosion Test (C.C.T)

Cyclic Corrosion Test CORR Auto

Water Resistance Test Chamber – Humidity Test

Kesternich Corrosion Chamber – SO2

Gravelometer / Stone Chip Resistance Test

IPX9K Code

Fanpage