Gravelometer / Stone Chip Resistance Test

EQNA GR DIN_ISO_VDA

Equilam N.A. - USA

12 months

The Gravelometer, or Chipping Resistance Tester, is designed to rigorously meet the technical standards of ASTM D3170, SAE J400, ISO 20567-1, DIN 55996-1, and VDA. For other standards, please contact us. Contact Us: Email: secovina@vnn.vn OR Mr. Felipe Rojo, Email: frojo@equilamna.com , Phone: 1.754.900.7816 .

secovina@vnn.vn

HOTLINE TƯ VẤN : 0908866933

Gravelometer / Stone Chip Resistance Test

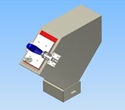

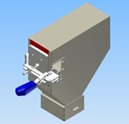

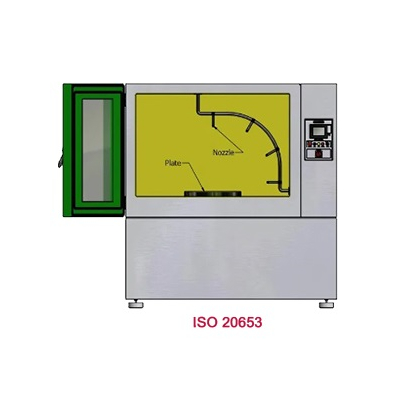

The Gravelometer, or Chipping Resistance Tester, models EQNA-GR-ASTM/SAE and EQNA-GR-DIN/ISO/VDA, is designed to rigorously meet the technical standards of ASTM D3170, SAE J400, ISO 20567-1, DIN 55996-1, and VDA. For other standards, please contact us.

This equipment simulates the impact of projectiles on metal sheets and coated three-dimensional parts, with the aim of evaluating the coating’s resistance to chipping. The Chip Resistance Tester is engineered to accurately replicate the effects of impacts on an automobile’s surface, ensuring a close correlation with real-world operating conditions.

The primary purpose of the test is to evaluate the coating or organic surface system on flat test panels. However, this type of testing may also be extended to finished (3D) parts or other materials, such as anodized aluminum or coated plastics, as long as the results are interpreted within the limitations and intentions outlined in the original test procedures.

The process involves impacting standardized projectiles, propelled by a jet of compressed air that passes through a nozzle, under controlled pressure, onto the test specimen. These tests are typically conducted at room temperature or under subzero conditions (e.g., −29°C ± 3°C), ensuring that the compressed air, projectiles, and the entire system are at the proper temperature.

In some cases, test specimens are pre-cooled in a freezer and then quickly transferred to the Gravelometer at room temperature for testing. However, this practice is not recommended, as temperature discrepancies between the projectiles and the compressed air can lead to distorted results.

After testing, various methods can be used to evaluate the specimens. The most common approach is to compare the tested samples with reference images provided in the applicable technical standards.

TECHNICAL SPECIFICATIONS

- The Gravelometer EQNA GR DIN_ISO_VDA, have the structure build in steel, with paint high strength epoxy;

- Dispose in the cylinder compressed air is 90 liters with certified of hydrostatic test, of high capacity for maintenance of pressure and compressed air flow required during the test;

- Accordance the require of ASME code, equipment manufactured under pressure vessel;

- Pressure gauge with pressure indication in the units: (bar;kgf/cm²; psi)

- Casters in polymer for facility the moving;

- All the electric components had register in UL/CE;

- Building accordance with the UL508a/CE (not included certificate, consult us);

- “Pulse-Stop” for prevent the vibration during the test;

- Power 208 +/- 10% Vac +/- 10% - 50/60 Hz;

- Emergency button;

- Security automatic system of operator with view LED indicator; for position of sample and abrasive collection drawer;

- Digital timer for counting the test time specified in the standard;

- Digital timer of current cycle , for determined the life of the abrasives;

- Digital timer of total cycle realized that equipment;

- Abrasive inlet with control of vibration intensify, that possibility the flow control, accordance the standards;

- Clean system and pressure adjusted – after test;

- Pressure gauge with certificate.

- Certificate of hydrostatic test in the air compressor tank.

OPTIONAL ACESSORIES

|

EQOP.0009 |

Filter for air compressed line. |

|

|

EQOP.0033 |

Packing EQNA GR SAE/ASTM or DIN/ISO/VDA; Wood box with pallet. |

|

|

EQOP.0057 |

54° Target chamber for DIN/ISO/VDA |

|

|

EQOP.0058 |

Impact Chamber 90° |

|

|

EQOP.0059 |

Impact Chamber 135° |

|

|

EQOP.0061 |

Impact Chamber 3D |

|

|

EQOP.0081 |

Chilled iron grit 0.14”- 0.18” (3.55 a 4.50 mm) Traceable certificate Packing with 2.42lbs. (1.100Kg) |

|

|

EQOP.0082 |

Worn River Gravel 0.37”- 0.62” (9.5 - 15.9 mm) Traceable certificate Packing 3.31lbs. (1.5Kg) |

|

|

EQOP.0083 |

Crushed granite 0.10” – 0.20” (2.5 – 5.0 mm) Traceable certificate Packing 3.31lbs. (1.5Kg) |

|

|

EQOP.0084 |

Crushed granite 0.20” – 0.51” (5.0 – 13.0 mm) Traceable certificate Packing 3.31lbs. (1.5Kg) |

|

|

EQOP.0085 |

Cast steel shot 0.07”- 0.11” (1.7 - 2.8 mm) Traceable certificate Packing 2.42lbs. (1.100Kg) |

|

|

EQOP. 0163 |

Crushed basalt 0.094" – 0.189” (2.4mm – 4,8 mm) Traceable certificate Packing 3.31 lbs (1.5 Kg) |

|

|

EQOP.0168 |

Crushed basalt 0.189” – 0.315” (4.8 mm – 8.00 mm). Traceable certificate Packing 3.31 lbs (1.5 Kg) |

|

|

EQOP.0157 |

Cooling system (MAP) with complete enclosure of the equipment for working up to -30°C, +/- 2°C, with access doors for work. Voltage: 208 ~ 220 -3-60 – other consult us

External dimension (W x D x H): 108.3”x 47.2”x 71.6” (2,750 x 2,200 x 1,820 mm) – included MAP Internal dimension (W x D x H): 86.2”x 37.9”x 54.5” (2,190 x 965 x 1,385 mm)

Chamber: Wood package (W x D x H): 114.2”x 62.9”x 86.6” (2,900 x 1,600 x 2,200 mm) Total weight: 2,646 lbs (1,200 Kg) MAP: Wood package (W x D x H): 74.8”x 47.2”x 90.6” (1,900 x 1,200 x 2,300 mm) Total weight: 1,764 lbs (800 Kg)

- Included: EQOP.0176 |

|

|

EQOP.0158 |

Cooling system (MAP) with complete enclosure of the e quipment for working up to -20°C, +/- 2°C, with access doors for work. Voltage: 208 ~ 220-3-60 – FLA 65 – other consult us

External dimension (W x D x H): 108.3”x 47.2”x 71.6” (2,750 x 2,200 x 1,820 mm) – included MAP Internal dimension (W x D x H): 86.2”x 37.9”x 54.5” (2,190 x 965 x 1,385 mm) |

|

|

|

Chamber: Wood package (W x D x H): 114.2”x 62.9”x 86.6” (2,900 x 1,600 x 2,200 mm) Total weight: 2,646 lbs (1,200 Kg) MAP: Wood package (W x D x H): 74.8”x 47.2”x 90.6” (1,900 x 1,200 x 2,300 mm) Total weight: 1,764 lbs (800 Kg)

- Included: EQOP.0176 |

|

|

EQOP.166 |

Pressure gauge certificate for pressure control. |

|

|

EQOP.167 |

Air compressor tank certificate accordance ASME code section VIII. |

|

|

EQOP.0172 |

Acoustic cabinet for enclosing the Gravelometer, to reduce the noise level during the test, < 85 dB measured at a distance of one meter at angle of 90°. Test control panel on the outside of the acoustic cabinet. External Dimension: L x W x H = 83.85"x 47.10"x 50.67" (2,130 x 1,196 x 1,287 mm). Wood packaging dimension: W x D x H = 94.5” x 51.2” x 50.1” (2,400 x 1,300 x 1,500 mm) - Approximate Gross Weight: 650.36 lbs (295Kg). |

|

|

EQOP.0176 |

Upgrade of the gravelometer to work in a cold room, with a maximum distance of 197” (5 meters) between the gravelometer located inside the cold room and the laboratory at room temperature (for more details, contact us). |

|

Bình luận

Sản phẩm cùng loại

Salt Spray (Salt Fog)

Cyclic Corrosion Test (C.C.T)

Cyclic Corrosion Test CORR Auto

Water Resistance Test Chamber – Humidity Test

Kesternich Corrosion Chamber – SO2

Accelerated Weathering Tester – UV

IPX9K Code

Fanpage