Cyclic Corrosion Test (C.C.T)

C.C.T

Equilam N.A - USA

12 months

The EQUILAM NA C.C.T Cyclic Corrosion Test chambers provide the best simulation for accelerated corrosion testing. Some studies indicate that the tests results closely resemble those obtained in outdoor exposure. Samples can be exposed to different environmental conditions. Contact Us: Email: secovina@vnn.vn OR Mr. Felipe Rojo, Email: frojo@equilamna.com , Phone: 1.754.900.7816

secovina@vnn.vn

HOTLINE TƯ VẤN : 0908866933

Cyclic Corrosion Test (C.C.T)

The EQUILAM NA C.C.T Cyclic Corrosion Test chambers provide the best simulation for accelerated corrosion testing. Some studies indicate that the tests results closely resemble those obtained in outdoor exposure. Samples can be exposed to different environmental conditions, including:

Salt Spray (Salt Fog) – ASTM B117 – ISO 9227 – JIS Z 2371 – DIN 50021

Salt Spray (Salt Fog) with alternate solution – ASTM B117 – ISO 9227 – JIS Z 2371 – DIN 50021

Salt Spray – Prohesion (optional)

Stress or Spray can be oscillating or fixed (optional)

Immersion (optional)

Dry Off – Injection of hot, dry air

Warm saturated humidity condensed over samples (ISO 6270-2 – CH – ASTM D2247)

Warm saturated humidity (water fog) – ASTM D1735 (optional)

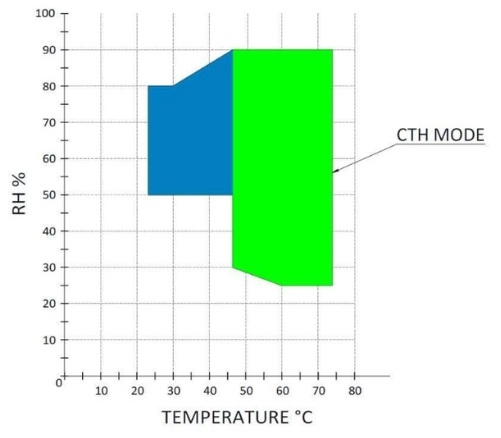

CTH: Temperature vs. Relative Humidity (see green chart)

Others upon request

Cyclic Corrosion Test CCT

The EQUILAM NA Cyclic Corrosion Test (C.C.T) Chambers are built with:

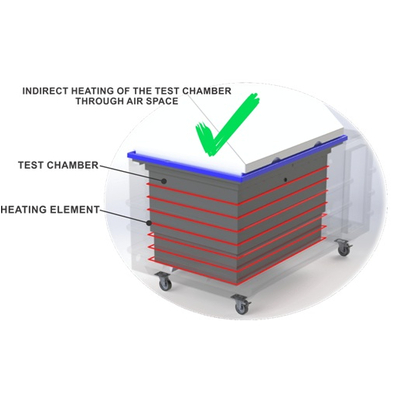

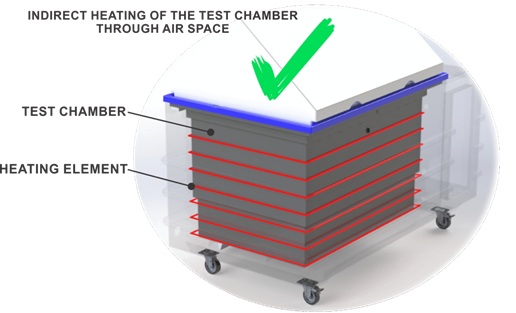

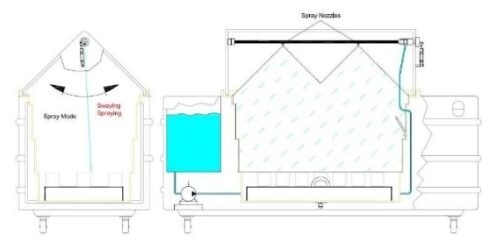

Indirect heating of the test chamber through hot air space, as illustrated in the diagram below. Therefore, electric heating elements inside the internal test chamber are not allowed.

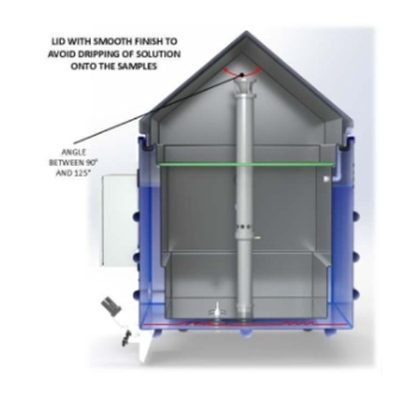

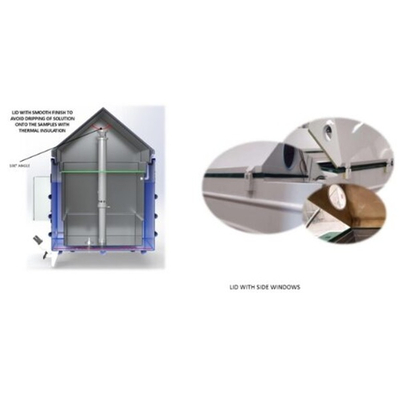

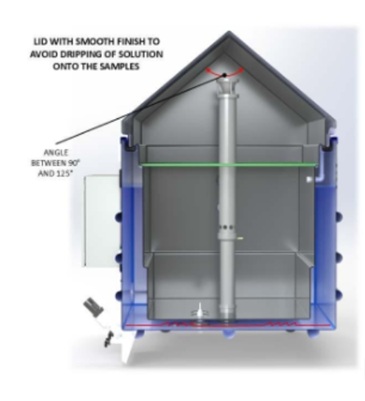

Lid with smooth internal finish; no structural elements are allowed on the inner side of the lid. It must have an angle between 90 and 125 degrees. The construction material must be hard enough to resist scratching from salt crystals in order to prevent grooves that could cause dripping onto the specimens, which would increase localized saline concentration and distort test results.

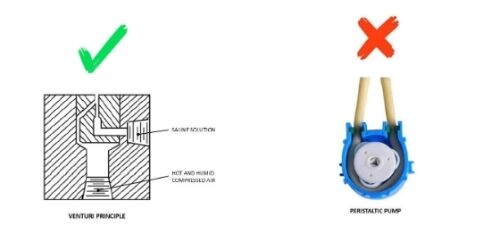

Atomizing nozzle must produce a fine fog, not droplets (peristaltic pumps). It must operate on the Venturi principle (ASTM B117), as peristaltic pumps are not recommended. The pressure of the bubble tower can control the distance of the atomization flow. Solution droplets are not acceptable during the atomization process.

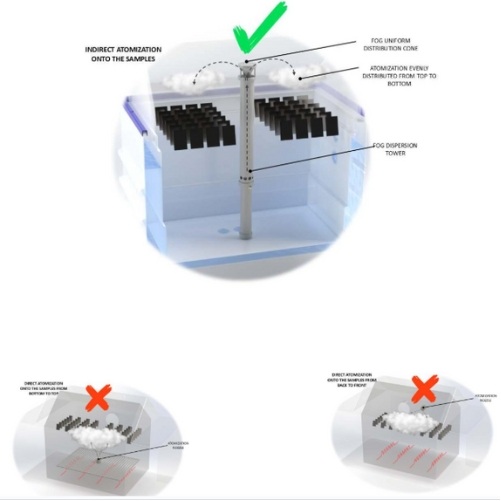

ASTM, ISO, and JIS standards require that the saline solution be atomized indirectly onto the samples; therefore, direct atomization over the specimens must never occur. The fog flow (atomized saline solution) must be evenly distributed from top to bottom (floor), and the use of a fog dispersion tower with a cone is recommended. Fog collection is critical to achieving optimal test results. Uniform and consistent collection is required by ASTM, ISO, and JIS technical standards.

Internal Chamber Dimensions:

The chamber must be designed to ensure homogeneity and proper distribution of the fog (spray). Internal chambers smaller than 35.3 cu. ft (1 m³) can cause undesirable effects in fog (spray) distribution, dry-off, temperature control, turbulence presence, and insufficient distances between the inner walls of the test chamber and the atomizing nozzles, as well as between the nozzles and the specimens. (ASTM)

Sample Positioning Inside the Test Chamber:

The positioning of test specimens in the salt fog chamber during testing must comply with the following conditions:

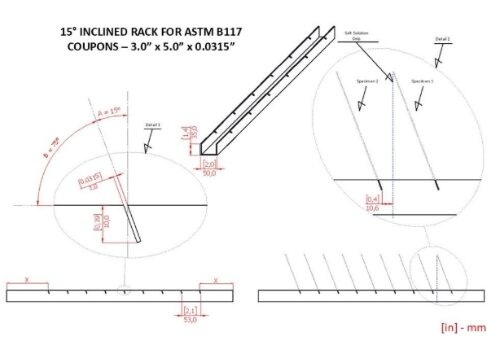

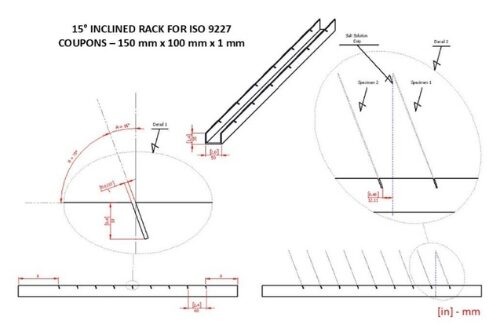

Specimens must be supported or suspended with the surface of interest facing upward at an angle between 15° and 30° from the vertical. It is recommended that the specimen orientation within the chamber be consistent to minimize variability.

Specimens must not come into contact with each other or with any metal.

Each specimen must be positioned to allow unobstructed exposure to the fog.

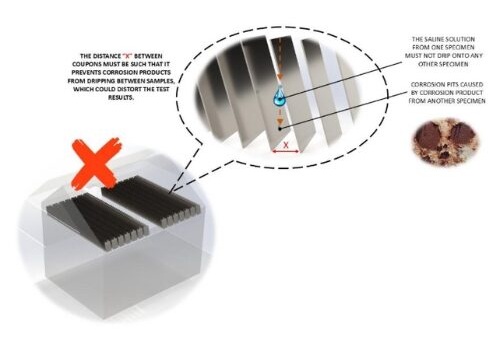

Saline solution dripping from one specimen must not fall onto another.

The positioning of specimens may also be defined by agreement between the parties involved.

Recommended Positioning of Coupons (ASTM B117):

Proper positioning of coupons is recommended to prevent corrosion products from dripping from one coupon onto another, thereby avoiding distortions in the test results.

Proper positioning of coupons, ISO 9227, is recommended to prevent corrosion products from dripping from one coupon onto another, thus avoiding distortions in the test results.

Quality: Salt / Corrosive Agents / Water / Compressed Air:

Control of these items is essential for the accuracy of the test results.

Salt Quality Specifications:

Salt (NaCl) purity limits and concentrations of undesirable chemical elements must be considered. Refer to ASTM B117, ISO 9227, JIS Z 2371, among others. Please refer to our CORRO SALT.

Water:

Water must comply with ASTM D1193 – Type IV (Max. 5 µS/cm). Water deionizers are recommended to achieve the required water quality.

Compressed Air:

The compressed air supply to the bubble tower (saturator) must be free of grease, oil, and dirt before use, having passed through filters. This air must be maintained at sufficient pressure at the base of the bubble tower to meet the working pressure requirements.

Main Technical Standards for Cyclic Corrosion – Corrosion Test Chambers – C.C.T Models:

ASTM D5894, ASTM G85 , BMW PA-P-029, FORD CETP: 00.00-L-467, FORD TM 00.00-L-467, GMW 14872, Honda CCT, Honda Structural, IEC 60068-2-52, ISO 11997-1 and 2, ISO 12944, ISO 12944, ISO 16701, ISO 19453-4, JAGUAR TPJLR.52.252, JAGUAR TPJLR.52.265, JAGUAR TPJLR.52.554, JOHN DEERE JDQ 178, MERCEDES BENZ MBN 10518, MIL STD 810D Method 509.2, MIL STD 883 Method 1009.5, NISSAN CCT I,II,IV, RENAULT D 17 2028 C, RTCA/DO-160E, SAE J2334, SCANIA STD 4233, SCANIA STD 4319, SCANIA STD 4445, TESLA TP0000808, TOYOTA TSH 1555G, VDA 232-102, VDA 621-415, VOLVO STD 1027,1375, VOLVO STD 1027,14, VOLVO STD 423-0014, VW PV1209, VW PV1210, YAMAHA YGK-8-501.

|

Model |

C.C.T 15-450

|

C.C.T 28-810 |

C.C.T 45-1200 |

C.C.T 110 -3100 |

C.C.T 135-4000 |

|

I.D. (w x d x h) |

|

|

|

|

|

|

Inches |

32.3” x 25.6” x 30.7” |

46.9” x 32.8” x 32.7” |

59.” x 35.4” x 35.4” |

98.4” x 49.2’ x 39.0” |

122” x 49.2” x 39.0” |

|

mm |

820 x 650 x 780 |

1,190 x 820 x 830 |

1,500 x 900 x 900 |

2,500 x 1,250 x 991 |

3,100 x 1,250 x 991 |

|

No included lid. |

|

|

|

|

|

|

Internal Volume Included lid. |

|

|

|

|

|

|

Cu.ft |

14.7 |

28.6 |

42.9 |

109.4 |

135 |

|

Liters |

415 |

810 |

1,200 |

3,097 |

3,840 |

Note: The C.C.T series chambers are designed as a monoblock, meaning the solution tank and the Bubble Tower (Saturator) are integrated into a single unit.

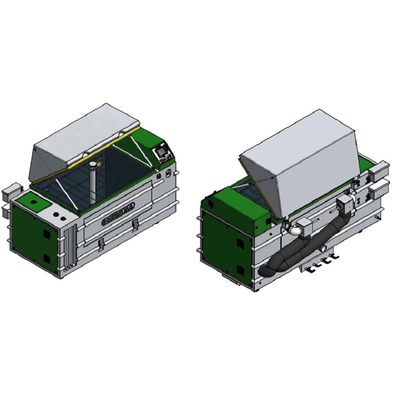

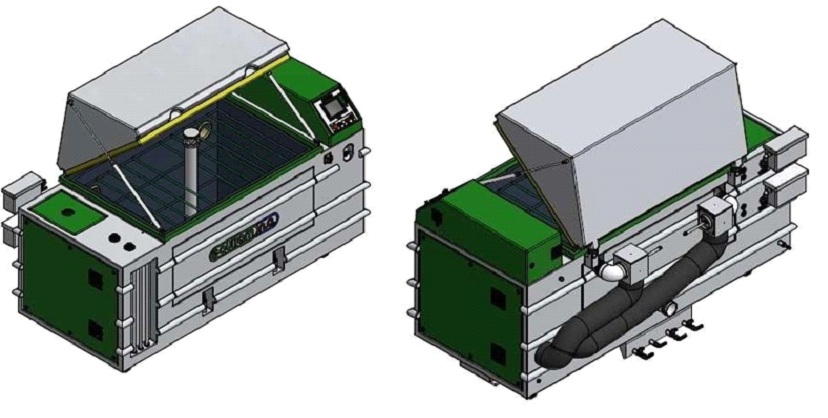

Illustrative photo C.C.T 110 -3100

Illustrative photo C.C.T 45-1200

|

Model |

14-500 |

18-700 |

40-15000 |

55-20000 |

77-30000 |

|

I.D. (w x d x h): |

|

|

|

|

|

|

Inches |

78.7” x 78.7 x 98.4” |

118.1” x 78.7” x 98.4” |

137.8” x 137.8” x 98.4” |

196.9” x 137.8” 98.4” |

275.6” x 137.8” x 98.4” |

|

mm |

(2,000 x 2,000 x 2,500) |

(3,000 x 2,000 x 2,500) |

(3,500 x 3,500 x 2,500) |

(5,000 x 3,500 x 2,500) |

(7,000 x 3,500 x 2,500) |

|

No “V” celling |

|

|

|

|

|

|

Door clearance: |

|

|

|

|

|

|

Inches |

59.0” x 82.6” |

59.0” x 82.6” |

118.1” x 83.8” |

118.1” x 83.8” |

118.1” x 83.8” |

|

mm |

1,500 x 2,100 |

1,500 x 2,100 |

3,000 x 2,130 |

3,000 x 2,130 |

3,000 x 2,130 |

|

Internal Volume Included lid: |

|

|

|

|

|

|

Cu.ft |

494.4 |

642.7 |

1,412 |

1,942 |

2,719 |

|

M³ |

14 |

18.2 |

40 |

55 |

77 |

Walk-In C.C.T Dimensions: (Above are example dimensions. As construction is penalized, custom dimensions are available upon request.)

Illustrative photo W.C.C.T 14-500 Illustrative photo W.C.C.T 55-200000

WHY EQUILAM NA - Cyclic Corrosion Test (C.C.T.)

EQUILAM NA Cyclic Corrosion Test (C.C.T) Chambers are constructed both internally and externally from non-metallic composite material (US PATENT 10371623). Therefore, there are no metallic parts inside the chamber, ensuring that no galvanic corrosion occurs and that test results remain free from distortion.

The programmable touchscreen control panel of the EQUILAM NA Cyclic Corrosion Test (C.C.T) series allows programming alternating cycles with multiple modes, including ramps and plateaus that closely simulate real-world weathering conditions.

Salt Spray (Salt Fog) Mode:

Test specimens are placed inside the test chamber following established technical standards or company-specific protocols. They are exposed to controlled fog containing corrosive agents (acidic/saline) in a high-humidity environment, using solutions specified by industry standards.

Prohesion Mode (optional):

Test specimens are placed inside the test chamber and exposed to an atomized solution at ambient temperature. In this mode, compressed air does not pass through the saturator.

Stress (Spray) Mode – Oscillating or Fixed:

This optional mode is also available in a fixed configuration or as a suspended oscillating system (mounted at the top of the chamber).

Immersion Mode (optional):

The solution is pumped into the test chamber, immersing the test specimens. This solution can be either heated or maintained at ambient temperature.

Dry Off Mode:

Hot dry air is injected into the test chamber to dry the specimens.

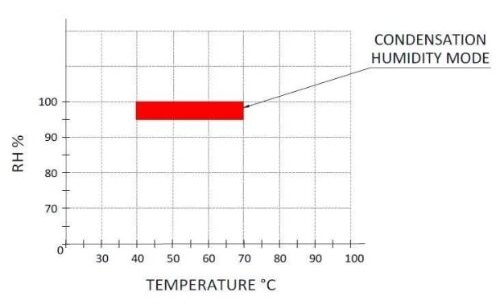

Condensed Humidity Mode:

Warm saturated humidity is condensed onto the specimens (ISO 6270-2 – CH – ASTM D2247).

Water Fog Mode – ASTM D1735 (Optional):

Test specimens are placed inside the test chamber following established technical standards or company-specific protocols. They are exposed to a fog generated with deionized water, and the test chamber is maintained at a high humidity level.

CTH Mode (optional):

With temperature vs. relative humidity control within the green zone of the graph below.

To reach the blue zone of the graph, the laboratory where the cyclic corrosion test (CCT) chamber is installed must maintain an ambient temperature ≤ 69.8°F (21°C) and relative humidity ≤ 50%.

Otherwise, a cooling and relative humidity control system (ECAX) is required.

Care Must Be Taken to Avoid Cross Chemical Contamination to Prevent Distortion of Test Results:

When a neutral salt spray corrosion chamber has previously been used for an acid test—AASS / CASS—or with any other solution (chemical product – corrosive agent) not specified by standards such as ASTM B117, NSS–ISO 9227, or NSS–JIS Z2371, or if it has been used for any purpose other than neutral salt spray testing, the chamber becomes chemically contaminated. The reverse scenario also results in contamination.

Therefore, a neutral salt spray chamber must undergo a complete cleaning procedure until the pH level complies with technical standard guidelines. The corrosivity of the chamber must also be verified to ensure it does not significantly affect the results of subsequent tests.

It is essential to note that this cleaning process is challenging, and achieving full decontamination is nearly impossible. (ISO 9227).

Lid at a 100-Degree Angle:

Made of high-strength plastic resistant to scratching by salt crystals.

(Acrylic can be scratched by salt crystals, which may lead to dripping onto the samples — an undesirable condition.)

If the user requires sample visibility, it’s important to note that during the test, direct observation is not possible.

Our solution is to include side windows in the lid, thus avoiding any dripping onto the specimens.

A minimum test chamber volume of 1000 liters is recommended (excluding the volume of the lid). Smaller chamber volumes can lead to turbulence, which may distort the final test results.

Electrical panel with UL label, protected against water splashes and dust.

Bubble Tower (Air Saturator Tower or Humidifying Tower) made of stainless steel, automatic.

All electrical components have a UL label.

Emergency stop switch provides immediate shutdown to prevent accidents.

Lockable switch that allows shutdowns for preventive or corrective maintenance.

- Safety relay that interrupts electrical circuits whenever faults or accident risks are detected.

- Lid opening/closing sensor: When the lid is opened to inspect the samples during the test, spraying and heating of the chamber and saturator are automatically disabled, saving energy and increasing user safety.

- Panel with industrial-grade colored LED indicators, providing visual and audible signals to indicate the status of the machine and its respective processes.

- Solution tank levels, deionized water in the saturator tower, and water jacket levels are located on the front side and are easy for the operator to view, in addition to having electronic safety level controls.

Optional Accessories:

- pH meter for measuring the pH of the solution to be atomized and of the fog collected during the test.

- Conductivity meter for measuring the conductivity of deionized water (ASTM D1193 Type IV).

- Densimeter for measuring the concentration of NaCl in the prepared solution.

- High-purity salt (NaCl) in accordance with ASTM B117.

- Data acquisition – Supervisory system.

- Hermetic DEI with a green LED indicating water compliant with ASTM D1193 Type IV, and a red LED for water outside ASTM D1193 Type IV specifications.

- Screw mounting support.

- Grid-type support for placing test specimens.

- Access port for cable pass-through.

- Field Evolution Certificate.

- CSA Certificate (Canada).

- Prohesion Mode. Immersion Mode.

- Stress or Spray Mode (oscillating or fixed).

- CTH Mode.

- Ultra Low Temperature Mode

- Low Temperature Mode

- Inclined rack for screws

- Inclined rack for coupons. The number of coupons per rack depends on the inclination (15° to 30°) and the height of the coupons, as the spacing between them must comply with the rule of preventing corrosion product dripping from one coupon onto another.

Bình luận

Sản phẩm cùng loại

Salt Spray (Salt Fog)

Cyclic Corrosion Test CORR Auto

Water Resistance Test Chamber – Humidity Test

Kesternich Corrosion Chamber – SO2

Gravelometer / Stone Chip Resistance Test

Accelerated Weathering Tester – UV

IPX9K Code

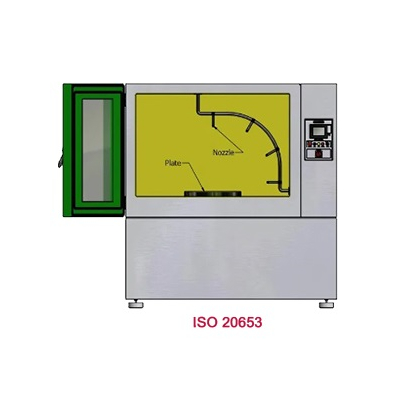

Fanpage