IPX9K Code

IPX9K Code

Equilam N.A - USA

12 months

IPX9K Code Test Chamber Standards : ISO 20653, IEC 60529. Contact Us: Email: secovina@vnn.vn OR Mr. Felipe Rojo, Email: frojo@equilamna.com , Phone: 1.754.900.7816

secovina@vnn.vn

HOTLINE TƯ VẤN : 0908866933

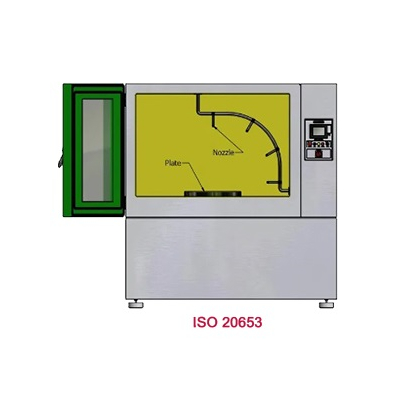

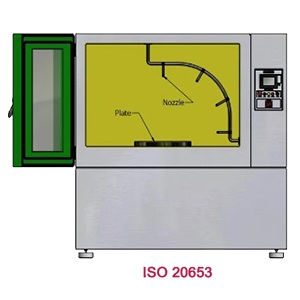

IPX9K Code Test Chamber

Device manufactured according with the requirements of the International and National Technical Standards for full service of the test’s specifications and characteristics for Degree of Protection (IP-Code) on enclosure of the electrical equipment.

The device installation according to the customer’s needed, being that, the use of the Walk-In and/or Drive-In Chamber are required to specimens of the bigger dimensions (samples larger dimension than 3,9”).

The test of protection degree IPX9 rate the protection efficient of enclosure for electrical device submit against water to water jet in different angles under the enclosure at high pressure and temperature.

Strictly meet the characteristics of built and test specification of the Technical Standards and their derivations:

IEC 60529, ISO 20653, Others (On request)

- The IPX9 device, , Equilam NA brand, has it’s built structure in stainless steel and high strength materials to meeting your test needs;

- Has a reservoir of 92 gal and/or according the need for design, with hydrostatic certificated and water system to heating and pressure;

- Jet nozzle according with the requirements and dimensions requested by IEC 60529 standard;

- Spray nozzle angle as per requirements of IEC 60529 standard, four positions (0°, 30°, 60° and 90°) for samples with dimensions smaller than 9,8”. In case of samples with dimensions bigger than 9,8”, the positions and quantify of spray nozzle must be in accordance with total wettability of enclosure surface;

- The device meets NR12 requirements;

- Pressure regulator valve;

- Gauge with pressure indication in the units: (bar;kgf/cm²; psi)

(0 ~ 10kgf/cm² +/- 0,1 Kgf/cm²)

- All electrical components with UL register;

- Supply voltage at 220 +/- 10% Vac +/- 10% - 50/60 Hz;

- Security automatic system of operator with visual LED indication;

- Cleaning and pressure adjustment system – pre-test;

Techical Specifications

|

Specifications |

Model - IPX9 Test |

|

Water temperature |

176°F ± 9°F (80°C ± 5°C) |

|

Room temperature |

77°F ± 14°F (25°C ± 8°C) |

|

Recommended relative humidity |

50% ± 5 |

|

Temperature units |

°C - °F |

|

Water flow rate |

14l/min - 16l/min |

|

Spray distance |

0°, 30°, 60° e 90° (for samples with smaller dimension than 9,8”) On request (for samples with the bigger dimension than 9,8”) – According requested IEC 60529 |

|

Water pressure |

100 ± 5 bar (1450,38 ± 72,52 psi) |

|

Test capability |

30s per nozzle (15l/min) |

|

Device dimensions |

On request (according to the needs of the project) |

|

Water tank dimensions (L x W x H) |

63” x 33” x 38” (1600 x 830 x 960 mm) |

|

Net Weight |

On request (according to the needs of the project) |

|

Gross Weight (with box) |

On request (according to the needs of the project) |

|

Necessary distance between enclosure and device |

|

|

Supplying |

220 VAC – 60 Hz – 16 A – Single-phase or accordance the needs of project |

|

Water quality |

ASTM D 1193 Tipo IV |

|

DI Water – Spray mode |

14l/min - 16l/min |

|

Spray nozzle connection |

1/4” |

Customer reference list

|

AUTO INDUSTRY |

APPLIANCE |

PAINT ELECTROPLATING |

UNIVERSITIES RESEARCH CENTERS |

METALLURGY |

|

Fiat |

Multibras |

Anjo Química |

ALAC |

Allevard |

|

Ford |

Bosch |

Akzo Nobel |

CTA S.J Campos |

Castrol |

|

General Motors |

BSH Continental |

Basf – Glasurit |

Falcão Bauer |

Cebrace |

|

Honda |

Electrolux |

Chemetall |

FEI IPEN |

Continental Teves |

|

Iveco Fiat |

GE – OSI |

Dorken |

IPEN - SP |

COSIPA |

|

Marcopolo |

|

Killing |

IPT – SP |

CSN |

|

Mercedes Benz |

|

Magni América |

ITAL |

Keko |

|

Peugeot Citroen |

|

Metalcoating |

PUC – Labelo |

Metagal |

|

Renault |

|

Niquelação Brasil |

SENAI |

Petrobras |

|

Scania |

|

PPG |

Erichsen – França |

Sachs |

|

Volkswagen |

|

|

Erichsen – Itália |

Shell |

|

Volvo |

|

|

|

Siemens |

|

Volkswagen |

|

|

|

Tramontina |

|

Ferrari – Itália |

|

|

|

Tenneco |

|

Honda – Tailândia |

|

|

|

Tower |

|

1 (One) Year Parts Warranty against manufacturing defects from date of delivery at customer's site. This assumes equipment is used under normal operating conditions in accordance to the instruction manual. This warranty does not apply to glassware (lamps). In case of non-warranty issues during warranty period, actual expenses shall apply. |

|

Note 1: All our equipment is delivered with Installation, Maintenance, and User Manuals. We believe this material is enough for the correct use of the equipment. We are available for further questions and clarifications. If necessary, we provide the service of assembling and staff training at client’s site (Cost for this service available upon request). |

|

Note 2: Appearance and specifications of equipment are subject to change without prior notice. |

Bình luận

Sản phẩm cùng loại

Salt Spray (Salt Fog)

Cyclic Corrosion Test (C.C.T)

Cyclic Corrosion Test CORR Auto

Water Resistance Test Chamber – Humidity Test

Kesternich Corrosion Chamber – SO2

Gravelometer / Stone Chip Resistance Test

Accelerated Weathering Tester – UV

Fanpage