Salt Spray (Salt Fog)

SSe Series

Equilam N.A - USA

12 Months

Salt Spray (Salt Fog) – ASTM B117 / ISO 9227 / JIS Z 2371 / ASTM G85 A1. This is the traditional technique to simulate corrosion in the laboratory, widely used to perform rapid corrosion tests on metal parts with organic or inorganic coatings. Its application mainly serves companies in the automotive, renewable energy, construction, plastics, aviation, oil and gas, paints, varnishes, electronics, chemical, metallurgical, and other industrial sectors.

secovina@vnn.vn

HOTLINE TƯ VẤN : 0908866933

Salt Spray (Salt Fog) – ASTM B117 / ISO 9227 / JIS Z 2371 / ASTM G85 A1

This is the traditional technique (ASTM B117 – ISO 9227 and JIS Z 2371 – DIN 50021) to simulate corrosion in the laboratory, widely used to perform rapid corrosion tests on metal parts with organic or inorganic coatings. Its application mainly serves companies in the automotive, renewable energy, construction, plastics, aviation, oil and gas, paints, varnishes, electronics, chemical, metallurgical, and other industrial sectors.

Corrosion chambers are widely used for quality control, qualification tests, and specimen comparisons (samples).

The construction characteristics of Salt Spray corrosion chambers are essential to ensure the repeatability and reproducibility of the tests. These tests are comparative and, therefore, must follow exactly the construction characteristics described in the standards: ASTM B117, ASTM B368, ASTM G85 A1, ISO 9227, JIS Z 2371.

However, since traditional accelerated corrosion methods cannot simulate the real weather conditions found in nature, such as hot/cold, humid/dry, pollutants, solar radiation, and atmospheres with concentrations of salts and acids, the test results often provide a false correlation in comparison with real weathering tests.

The C.C.T. and C.C.T. CORR AUTO models are cyclic corrosion test chambers, where samples are exposed to different environments (modes), with corrosive agents, condensed humidity (spray or condensation), temperature control (hot/cold), relative humidity (dry/humid), drying, soak, and immersion. The control panel of this equipment (PLC) allows programming of alternating cycles with various modes, including ramps and plateaus, which are close to real weathering. Even so, there are difficulties in approximating reality because there are particularities in each region of the planet with different weather conditions, pollution levels, and different atmospheric contaminants, making it difficult to match accelerated laboratory corrosion tests with real conditions.

We must be careful with cross chemical contamination to avoid distortions in the results: When the neutral salt spray corrosion chamber has been used for an acid test – AASS / CASS, or any other solution (chemical product – corrosive agent) different from those specified in the standards ASTM B117, NSS-ISO 9227, or NSS-JIS Z2371, or has been used for any purpose other than neutral salt spray, the chamber will be chemically contaminated. Furthermore, the reverse process also results in contamination.

Therefore, the neutral salt spray chamber must undergo a complete cleaning procedure until the pH reaches the level specified by the technical standards, and the chamber’s corrosivity must be verified to ensure it does not significantly affect the results of subsequent tests.

We emphasize that this cleaning is a difficult procedure, and decontamination is an almost impossible process to achieve. (ISO 9227).

Note: Some customized industry standards are derived from the traditional standards mentioned.

|

Model |

Serie SSe |

|||||

|

SSe 15-450 |

SSe 28-810 |

SSe 45-1200 |

SSe 110 -3100 |

SSe 135-4000 |

|

|

|

I.D. (w x d x h) |

|

|

|

|

|

|

|

Inches |

32.3” x 25.6” x 30.7” |

46.9” x 32.8” x 32.7” |

59.” x 35.4” x 35.4” |

98.4” x 49.2’ x 39.0” |

122” x 49.2” x 39.0” |

|

|

mm |

820 x 650 x 780 |

1,190 x 820 x 830 |

1,500 x 900 x 900 |

2,500 x 1,250 x 991 |

3,100 x 1,250 x 991 |

|

|

No included lid. |

|

|

|

|

|

|

|

Internal Volume Included lid. |

|

|

|

|

|

|

|

Cu.ft |

14.7 |

28.6 |

42.9 |

109.4 |

135 |

|

|

Liters |

415 |

810 |

1,200 |

3,097 |

3,840 |

|

Note: The EQUILAM NA – SSe series chambers are designed as a monoblock, meaning the solution tank and the Bubble Tower (Saturator) are integrated into a single unit.

|

Model |

Walk In |

||||

|

WSSe 14 - 500 |

WSSe 18 -700 |

WSSe 40 - 15000 |

WSSe 55 - 20000 |

WSSe 77 - 30000 |

|

|

I.D. (w x d x h): |

|

|

|

|

|

|

Inches |

78.7” x 78.7” x 98.4” |

118.1” x 78.7” x 98.4” |

137.8” x 137.8” x 98.4” |

196.9” x 137.8” 98.4” |

275.6” x 137.8” x 98.4” |

|

mm |

(2,000 x 2,000 x 2,500) |

(3,000 x 2,000 x 2,500) |

(3,500 x 3,500 x 2,500) |

(5,000 x 3,500 x 2,500) |

(7,000 x 3,500 x 2,500) |

|

No “V” celling |

|

|

|

|

|

|

Door clearance: |

|

|

|

|

|

|

Inches |

59.0” x 82.6” |

59.0” x 82.6” |

118.1” x 83.8” |

118.1” x 83.8” |

118.1” x 83.8” |

|

mm |

1,500 x 2,100 |

1,500 x 2,100 |

3,000 x 2,130 |

3,000 x 2,130 |

3,000 x 2,130 |

|

Internal Volume Included lid: |

|

|

|

|

|

|

Cu.ft |

494.4 |

642.7 |

1,412 |

1,942 |

2,719 |

|

M³ |

14 |

18.2 |

40 |

55 |

77 |

Walk-In Salt Spray Dimension: (Above are some example dimensions. The construction is panelized, therefore custom dimensions are available.)

Bình luận

Sản phẩm cùng loại

Cyclic Corrosion Test (C.C.T)

Cyclic Corrosion Test CORR Auto

Water Resistance Test Chamber – Humidity Test

Kesternich Corrosion Chamber – SO2

Gravelometer / Stone Chip Resistance Test

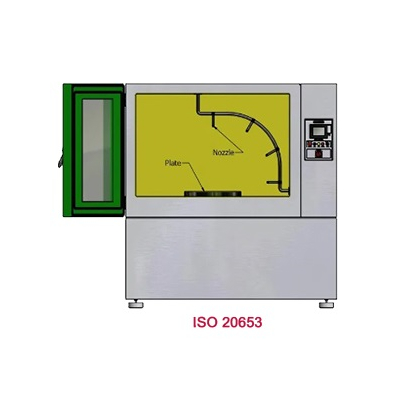

Accelerated Weathering Tester – UV

IPX9K Code

Fanpage