Product List

Product Search

Featured Products

Featured News

Online support

Tel: 0908866933 - secovina@vnn.vn

Thống kê truy cập

- Đang online 0

- Hôm nay 0

- Hôm qua 0

- Trong tuần 0

- Trong tháng 0

- Tổng cộng 0

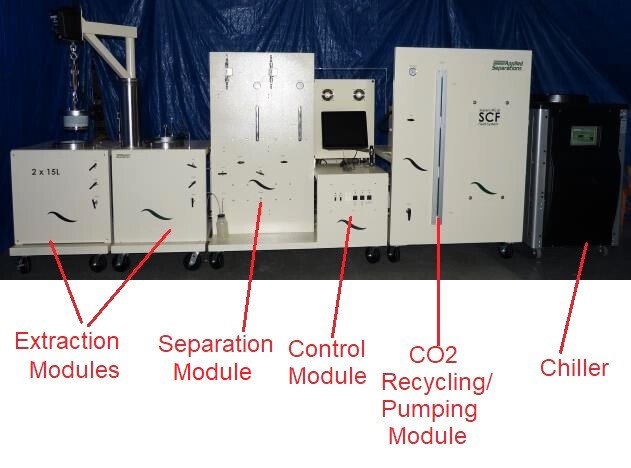

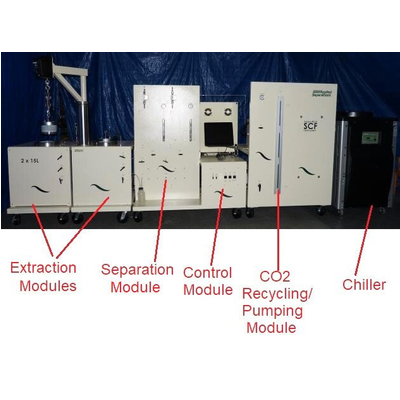

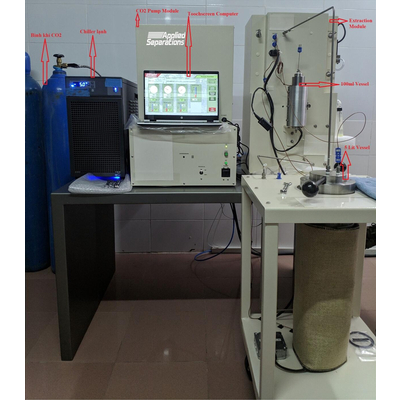

2 x 15 Liter Supercritical Fluid System

2x15 liter

Applied Separations

12 Months

2 x 15 Liter Supercritical Fluid System - Applied Separations, Inc.

Bình luận

Sản phẩm cùng loại

lab-scale supercritical fluid extraction

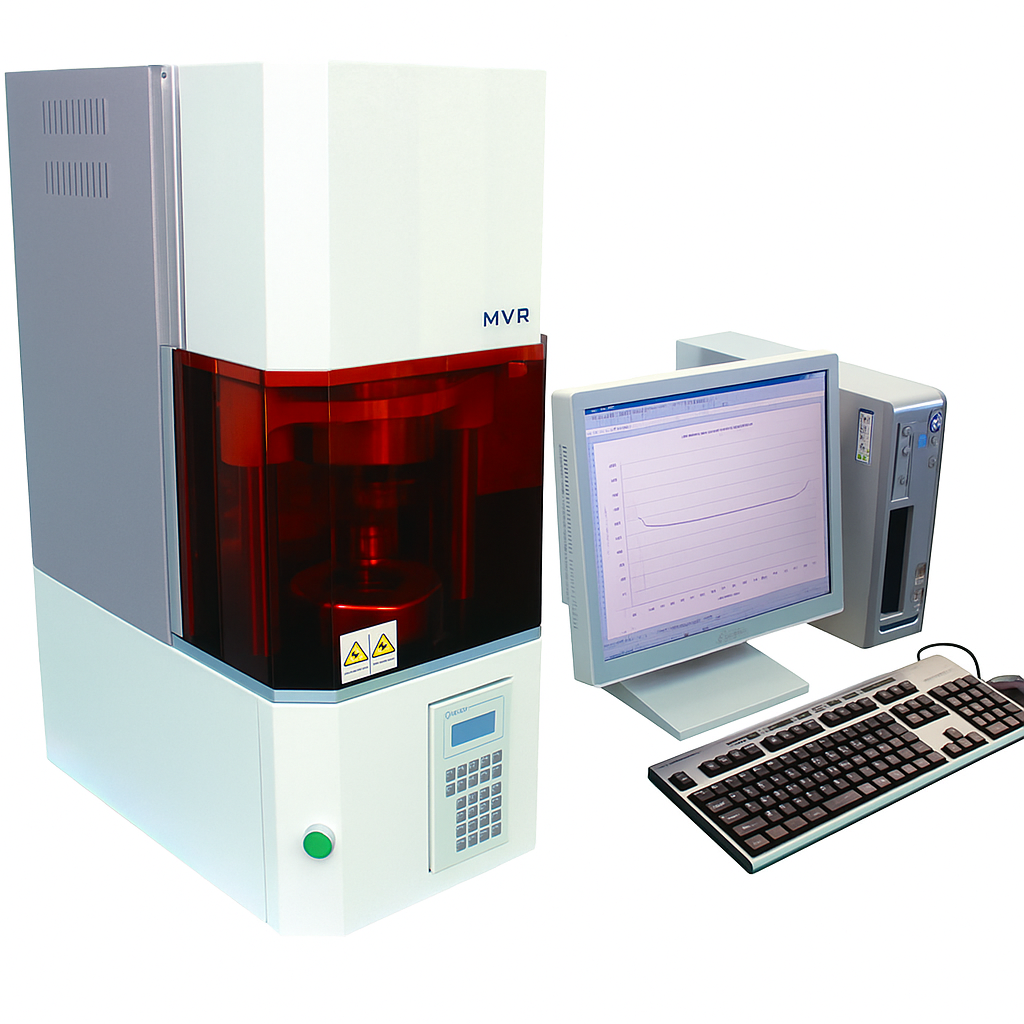

The Spe-ed™ SFE-2 and Spe-ed SFE-4 are the original SFEs in our series of instruments for supercritical fluid extraction.

Supercritical Fluid Extraction

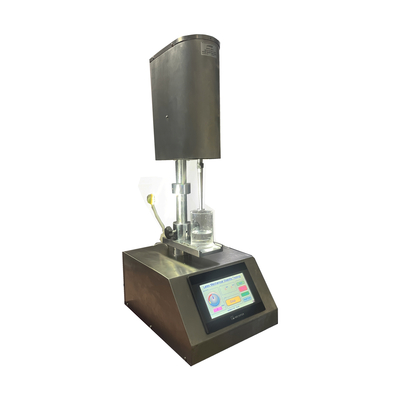

The Spe-ed SFE Basic is the entry-level SFE in our series of instruments for supercritical fluid processes. This no-frills machine satisfies the rigorous needs of research in the lab with a price tag that allows everyone to take advantage of the benefits of Supercritical fluids.

Spe-ed SFE-2/4 supercritical fluid extraction

The Spe-ed™ SFE-2 and Spe-ed SFE-4 are the original SFEs in our series of instruments for supercritical fluid extraction.

Helix Supercritical Fluid Systems

The Helix™ Laboratory Supercritical Process Development Unit is a modular system designed for maximum flexibility and scalability. Depending on your needs, this unit can be configured to handle a multitude of tasks, using only the modules you require for your specific process. Supercritical Fluid Systems.

100 liters Supercritical Systems

Applied Separations, Inc. offers SCF systems in any size and configuration. Although the size of a pilot system versus a production system is arbitrary, customarily, Applied Separations designates pilot systems as having extraction/reaction vessels from 5 liters to 100 liters. Greater than 80 liters, we consider production scale.