FPS WEAR TESTING SYSTEM

AB-2012

Ueshima Japan

12 months

A Lambourn abrasion tester or conventional FPS tester, which is used for abrasion tests of high polymer material for such products like tire and belt, controls slip ratio or speed difference between test piece and road wheel while doing an abrasion test.

* FPS stands for Field Performance Simulation.

secovina@vnn.vn

HOTLINE TƯ VẤN : 0908866933

AB-2012 FPS WEAR TESTING SYSTEM

Outline

A Lambourn abrasion tester or conventional FPS tester, which is used for abrasion tests of high polymer material for such products like tire and belt, controls slip ratio or speed difference between test piece and road wheel while doing an abrasion test.

AB-2012 FPS Abrasion Tester can perform tests by controlling tangential force between the test piece and the road wheel in addition to the conventional control of slip ratio, aiming more correlation to the real tires. It was necessary to repeat tests with different conditions in order to evaluate abrasion vs friction energy, which is deemed to have more correlation to the real tire.

The FPS abrasion tester enables to reproduce conditions of real tire more precisely by directly controlling the friction force.

* FPS stands for Field Performance Simulation.

Test Item

●Slip ratio regulation test

●Friction force regulation test

Feature

● Friction force regulation tests which were not available with conventional abrasion testers

● Real-time measurement and feed-back of test piece diameter for accurate speed and slip ratio control

● Control of abrasive wheel temperature without using a slip ring (RT+10℃ to 80℃ as standard)

● Simplified test piece transport system using the swing arm

●Improved test piece clamping system with a ratchet

● Use of the accurately controlled talc feeding system for adhesion preventing (Japan patent no. 4559617)

●High repeatability of test conditions with sandpaper used as abrasive

●Fully automatic tests of 56 (50-mm dia.) test pieces (Fully automatic tests of 24 (70-mm dia.) test pieces: optional)

●The brush cleans the surface of the road wheel to keep the conditions constant

●Friction energy analysis available with the exclusive software

Application

●Abrasion tests of rubber materials for tire, etc. ISO and JIS describes abrasion testers for rubber.

However, difference of test piece shapes, abrasives and methods may give different results because of the different wear mode. An optimum tester must be selected for the final product of the material and its usage conditions. The FPS abrasion tester is specially designed to get material abrasion result best correlated to that of automobile tires.

Measurement Item

●Test piece velocity (m/min)

●Road wheel velocity (m/min)

●Slip ratio (%)

●Load (N)

●Friction force (N) or torque (N・m)

●Test piece diameter (mm)

●Test piece surface temperature (℃)

●Road surface temperature (℃) (optional)

Specification

Name: FPS Abrasion Tester

Test Piece Shape: 50-mm dia. x 10-mm thick / 70-mm dia. x 20-mm thick (optional)

Road Wheel: 250-mm dia. x 30-mm thick (Abrasive: Sandpaper)

Load: 10 to 80N (The settings can be changed as desired.)Air cylinder drive load cell feedback control

Test Shaft Torque: -3 to 3Nm (Setting range)

Slip Ratio Setting: ±30%

Testing Velocity : Test piece: 10 to 210 m/min, Road Wheel: 10 to 150m/min

Automatic Testing: Automatic transportation and testing of test pieces stored on the turret

Continuous Operation: 56 pcs max. (50-mm dia. and 10-mm wide test pieces)/ 24 pcs max. (70-mm dia. and 20-mm wide test pieces, optional)

Surface Temperature: Non-contact thermometers (0 to 250°C for test piece and road wheel)

Road surface temperature control: RT+10℃ to 80℃

Dusting System: Talc feeder (0.1 to 0.8rpm)

Data Processing (PC): Condition setting, start/stop control, data acquisition, graph plotting, etc.

Safety Device: Emergency stop switch, door interlock, overload protection

Utility

Electric Power: 3-phs 200VAC, 30A 50/60Hz

Factory Air: 0.5MPa to 0.8MPa, about 200L/min

Usage Environment: According to JIS K 6250-2006

Dimensions: Approx. 1130(W)×576(D)×1855(H)mm

Weight: 380kg (incl. dust collector and air dryer)

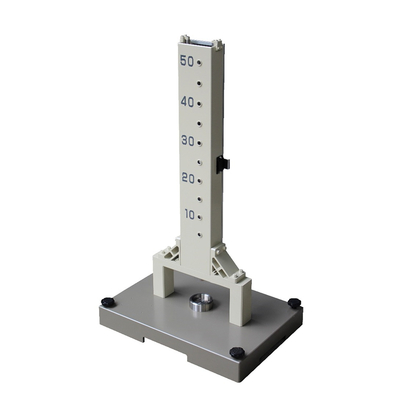

Accessories: Dust collector, air dryer, calibration tool, core metals, etc.

The PC is basically to be provided by the customer. The following PC specifications are recommended.

OS: Windows 10 or later, CPU: Intel Core i3 or higher, MEMORY: 8 GB or more, STORAGE: SSD 250GB or more

Monitor resolution: 1920 X 1080 or more.

Data communication: Wired LAN (1 port), RS232C (1 port)

Optionals:

●Electronic balance (with PC interface)

●Compact humidity conditioning case

●Sandpaper (#240, #120,♯ 80)

●Talc

●Mold for test pieces

Bình luận

Sản phẩm cùng loại

Constant-stress/strain flexometer

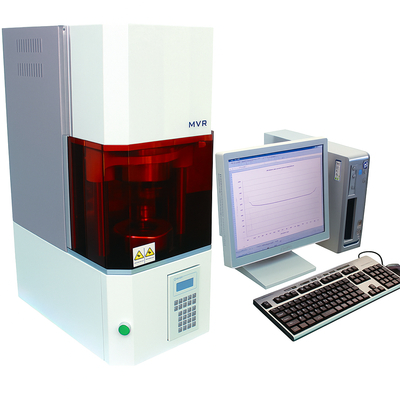

Mooney Viscometer

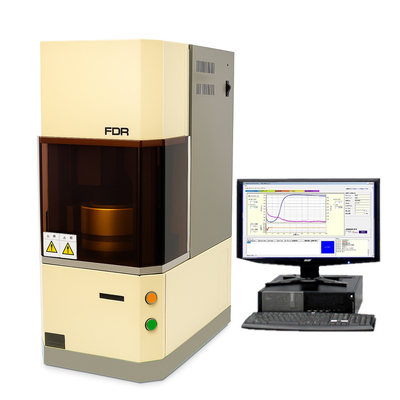

Flat Die Rheometer (FDR)

Dynamic Mechanical Analyzer (DMA)

Maron Type Mechanical Stability Tester

VR-6155

AB-1150 LAMBOURN ABRASION TESTER

TR Tester

Akron Abrasion Tester

Dupont Impact Tester

GEHMAN’S TORSION TESTER

Cable Abrasion Tester

Durometer Shore A - Shore D

Low Temperature Brittleness Tester

RTM Friction Tester (Tire)

latex mechanical stability tester

GEER’S AGING OVEN

Tensile testing machine

Pneumatic Drive Press Cutting Machine

Akron Abrasion Tester

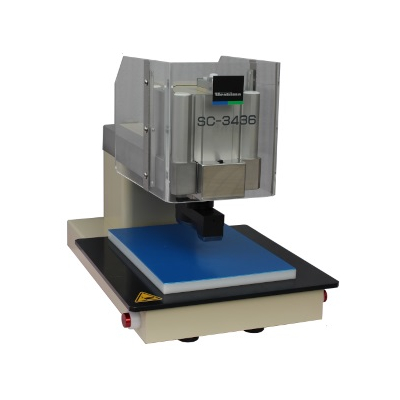

DIN Abrasion Tester

DEMATTIA FLEX CRACKING TESTER

Fanpage