Dynamic Mechanical Analyzer (DMA)

VR 7130

Ueshima

12 months

Ueshima Dynamic Mechanical Analyzer (DMA)

secovina@vnn.vn

HOTLINE TƯ VẤN : 0908866933

VR-7130 Automatic DMA was designed to minimize possible causes of measurement errors and variability by adopting the full automatic system and the unique temperature sensor. In combination with THERMO JETTER, it can measure viscoelasticity down to -90°C (-100°C as an option) without using liquid nitrogen.

A high-polymer material is a viscoelastic material, unlike elastic materials such as metals. In the case of elastic body, strain (response) comes up simultaneously to the given force (input). On the contrary, in case of a high polymer material, time lag will occur between input and response. These relations are different by the sample components and also dependent on temperature, velocity and strain. High polymer materials are used for various uses in various fields by using such characteristics.

As these properties are mainly treated as material properties, response to very minute input (force or strain) will be mainly measured. (Strain is measured to force or force to strain.) The VR-7130 has minimized possibility of human errors and realized excellent precision in viscoelasticity measurement of high-polymer materials.

Possible to load 100 max. samples automatically

Sample chucking, measurement and discharge are automated, thus minimizing human errors.

The temperature difference between the sample and the measurement point was solved by using a thermocouple with a rubber coating of the same thickness as the sample and adopting the step temperature control method.

In the measurement of viscoelasticity, minute deformations such as several μm to several tens of μm are measured, so the rigidity (deflection) of each component affects the test results. The DMA adopts a piezoelectric load cell to minimize deflection of the load cell itself, realizing more precise load measurement.

The compact body minimizes the influence of resonance and realizes accurate measurements within the measurement frequency of 0.1 to 200Hz (except for the character frequency of the sample).

Thermo Jetter cooling system enables measurement at low temperature down to -90°C(-100 °C as an option) without using liquid nitrogen

Direct calculation of the phase realizes improve measurement accuracy.

Master curve is available optionally.

Frequency: 0.1 to 200Hz (Variable)

Maximum load: 200N (with Load cell ±450N)

APPLICATIONS

Simulation of product property by test pieces

Tire: Abrasion/Friction/Rolling Resistance/Evolution of heat etc.

Car: Ride/Vibration-proof performance/noise

Other Vibration control and/or suppression/Sealing ability………

Molecular structure/degradation level etc.

MEASUREMENT MODES

Fixed point measurement

Temperature dispersion

Frequency Dispersion

Strain dispersion

MEASUREMENT ITEMS

Absolute complex modulus[E✽]

Storage modulus E’

Loss Modulus E’’

Tangent delta tanδ

SOFTWARE

Database software

Management of testing conditions

Management of testing results

Management of equipment conditions

Data backup

Measurement software

Test Condition Input Screen

Choice of testing mode:Fixed point measurement, Temperature dispersion, Frequency dispersion, Strain dispersion etc.

Setup of testing conditions:Testing temperature, frequency and strain

Sample conditions:Thickness, Breadth

Testing Screen

Real time indications while testing(Graph and numeric display)

Present conditions are available by status display. Error handling is easy also

Reporting output and text conversion(CSV form) after testing are possible

Master curve software

Viscoelasticity at high-frequency, under impossible conditions for actual testing, can be estimated by experimental formula

Low temperature property ⇒ High-frequency property

High temperature property ⇒ Low-frequency property

SPECIFICATION

Name Fully Automatic DMA

Model: VR-7130

Sample dimensions: Rectangular shape 40(L) x 4(W) x 2(t) mm

Testing method: Vertical tensile method

Sample convey system Automatic: 100 samples max.

Distance between chucks:20mm (Option: 10mm)

Load detection:(1)Load detector: Piezoelectric type load cell(Choose rating:±45N or±450N)

(2)Maximum load: 200N(with Load cell ±450N)

(3)Resolution: 1% F.S.

Displacement detection:(1)Displacement sensor: Optical fiber, non-contact type small displacement sensor

(2)Maximum displacement: 1,000μm

(3)Resolution: 0.3μm

Vibrator:(1)Vibration system: Electric vibrator (Lower chuck drive)

(2)Vibration waveform: Sinusoidal wave

(3)Vibration frequency: 0.1 to 200Hz continuously variable

(4)Vibration amplitude (strain): ±0.1 to ±2.5% (40 to 1,000μm p-p) continuously variable (±0.2 to ±5% in case of 10-mm chuck distance)

Initial tension (1)Mechanism: Lower side chuck tension by the vibrator

(2)Method: Constant strain method, constant load method (calculated to strain)

(3)Tension: 0μm to 2,000μm

Thermostatic chamber Framework: Opens and closes automatically

Testing temperature range: -90 to 200℃(optionallly down to -100℃ without using liquid nitrogen)

Safety device (1)Emergency stop switch

(2)Overheat limiter

(3)Pneumatic limiter

(4)Ground-fault circuit breaker

Connection for control: (1)Main unit control: USB

(2)Temperature control: RS-232C (D-SUB 9pin)

Utilities

(1)Main unit : Power source AC100V 1-phase 2kVA Dry air 0.4MPa

(2)Thermo Jetter:Power source AC200V 3-phase 4kVA Dry air 0.5MPa Flow rate 250L/min (under atmospheric pressure)

Usage environment:(1)Temperature : 5 to 40℃

(2)Humidity : 35 to 80%RH

Dimensions: Main unit and the rack: approx. 470 (W) x 470 (D) x 1320 (H) mm

Thermo Jetter (cooling air generator): approx. 510(W)x740(D)x1110(H) mm

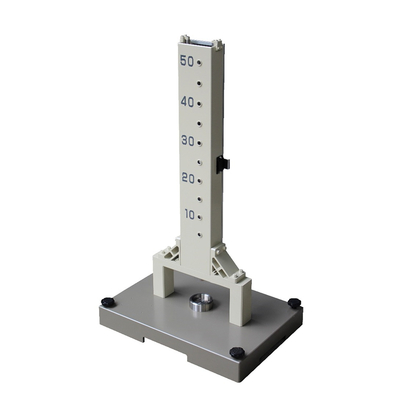

Accessories Load calibration tool, tool set and connection cables

OPTION

Master curve software

Temperature/strain dispersion, Temperature/frequency dispersion

Sample cutting blade, the exchangeable blade type

Bình luận

Sản phẩm cùng loại

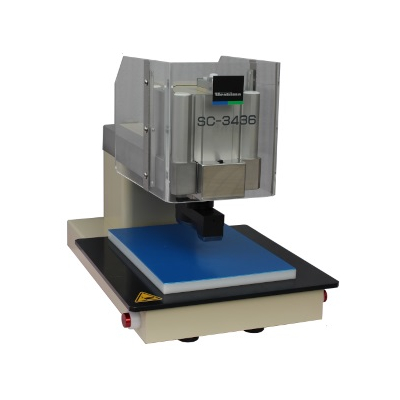

Constant-stress/strain flexometer

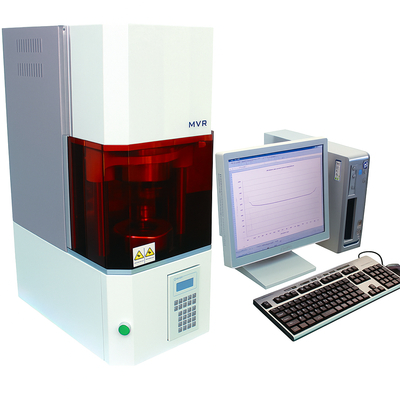

Mooney Viscometer

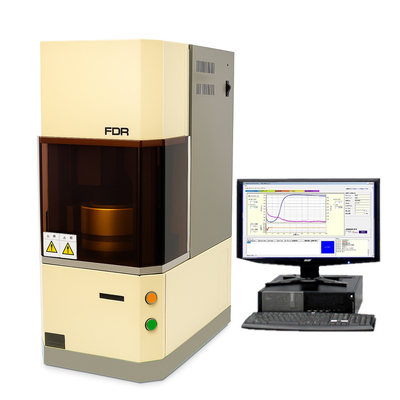

Flat Die Rheometer (FDR)

Maron Type Mechanical Stability Tester

VR-6155

AB-1150 LAMBOURN ABRASION TESTER

FPS WEAR TESTING SYSTEM

TR Tester

Akron Abrasion Tester

Dupont Impact Tester

GEHMAN’S TORSION TESTER

Cable Abrasion Tester

Durometer Shore A - Shore D

Low Temperature Brittleness Tester

RTM Friction Tester (Tire)

latex mechanical stability tester

GEER’S AGING OVEN

Tensile testing machine

Pneumatic Drive Press Cutting Machine

Akron Abrasion Tester

DIN Abrasion Tester

DEMATTIA FLEX CRACKING TESTER

Fanpage