GEER’S AGING OVEN

AG Series

Ueshima

12 months

Ueshima GEER’S AGING OVEN Most important functions like temperature uniformity, wind velocity and air ventilation rate are in accordance with JIS K 6257 and/or JIS K 7212. ○The minimized shape of the series allows use on a table. We also provide with an exclusive stand. ○It is able to place two units in tiers, minimizing the footprint.

secovina@vnn.vn

HOTLINE TƯ VẤN : 0908866933

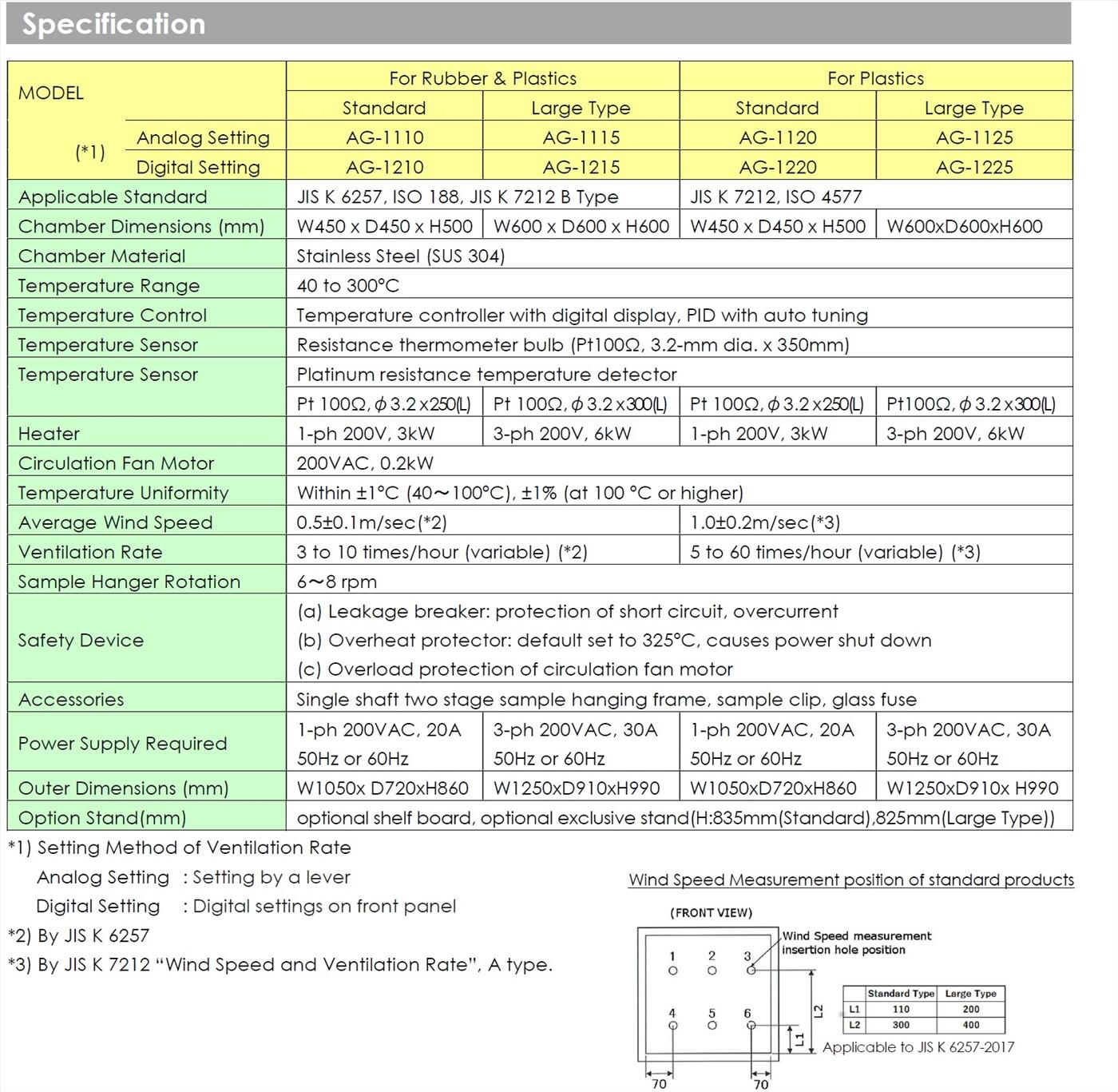

The Geer's Aging Oven is an oven for evaluating the durability of polymer materials against aging and deterioration due to heat and oxidation. This product exposes samples to an atmosphere where new heated air is constantly supplied at a specified rate, thus performing accelerated degradation. Depend-ing on the purpose, we have a total of 8 models for rubber and plastic, standard and large chamber dimensions, and digital and analog air replacement rate settings.

- Applicable Standard: JIS K6257/ISO188、JIS K 7212

Bình luận

Sản phẩm cùng loại

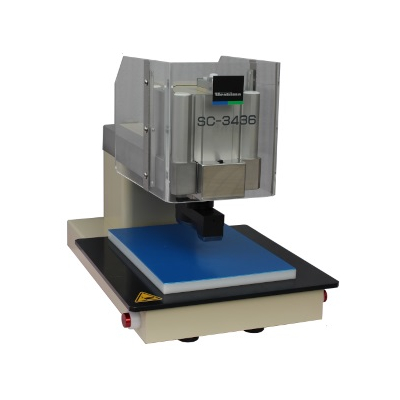

Constant-stress/strain flexometer

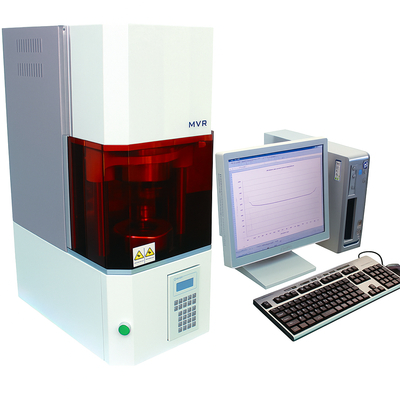

Mooney Viscometer

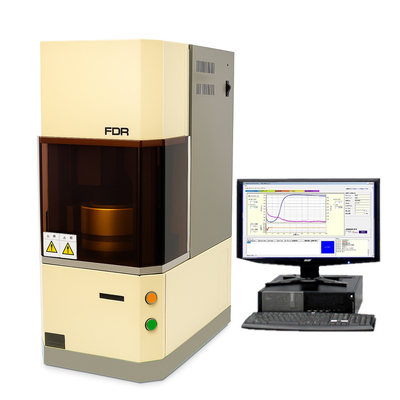

Flat Die Rheometer (FDR)

Dynamic Mechanical Analyzer (DMA)

Maron Type Mechanical Stability Tester

VR-6155

AB-1150 LAMBOURN ABRASION TESTER

FPS WEAR TESTING SYSTEM

TR Tester

Akron Abrasion Tester

Dupont Impact Tester

GEHMAN’S TORSION TESTER

Cable Abrasion Tester

Durometer Shore A - Shore D

Low Temperature Brittleness Tester

RTM Friction Tester (Tire)

latex mechanical stability tester

Tensile testing machine

Pneumatic Drive Press Cutting Machine

Akron Abrasion Tester

DIN Abrasion Tester

DEMATTIA FLEX CRACKING TESTER

Fanpage